Leave Your Message

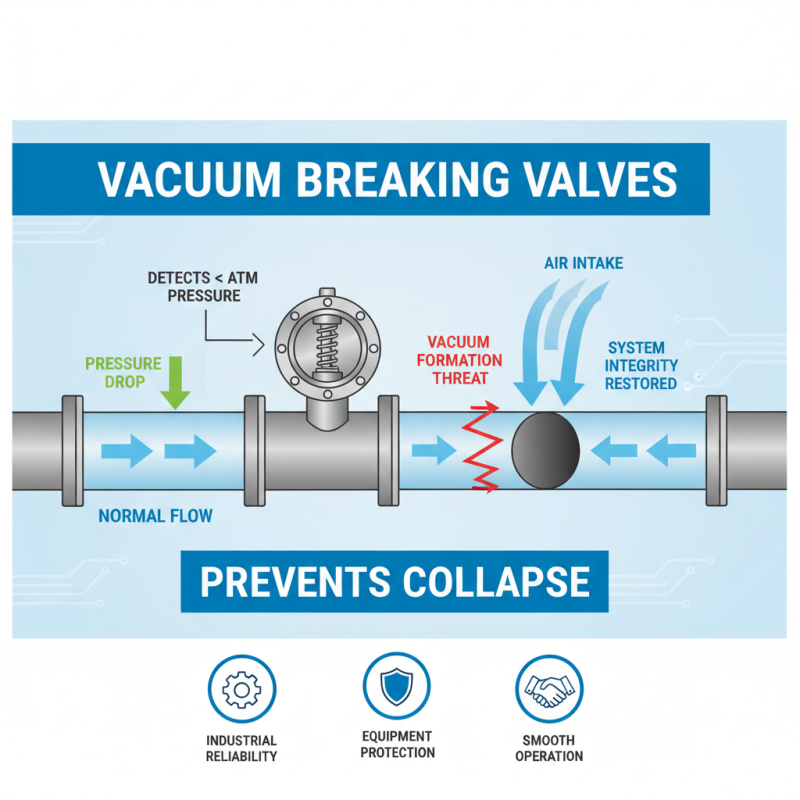

Vacuum Breaking Valves are integral components in various industrial applications, playing a crucial role in maintaining the safety and efficiency of systems that handle liquids and gases. As industries evolve and technology advances, understanding the significance of these valves becomes increasingly important. In 2025, the insights on Vacuum Breaking Valves will highlight their operational benefits, construction features, and the advancements that enhance their effectiveness in preventing vacuum conditions that could lead to equipment failure or hazardous situations.

The importance of Vacuum Breaking Valves cannot be overstated. These valves are specifically designed to protect pipelines and vessels from the detrimental effects of negative pressure, ensuring the integrity and safety of containment systems. With the growing complexity of industrial processes, the demand for reliable and efficient vacuum management systems is paramount. This article will explore the latest innovations and trends surrounding Vacuum Breaking Valves, providing invaluable knowledge for industry professionals aiming to optimize their operations and adhere to safety standards.

In summary, as we delve into the top insights on Vacuum Breaking Valves for 2025, we will uncover the critical role they play across various sectors. By understanding their importance, benefits, and advancements, industries can better safeguard their processes and enhance operational efficiency.

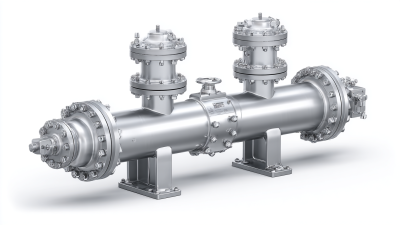

Vacuum breaking valves play a crucial role in a variety of industrial applications, particularly in processes that involve the handling of fluids in vacuum systems. As industries evolve, the necessity for maintaining proper pressure levels to prevent collapse or damage to pipelines has become increasingly significant. According to industry reports, the global market for vacuum breaking valves is expected to grow at a CAGR of 5.1% between 2023 and 2028, highlighting their essential function in enhancing operational safety and efficiency.

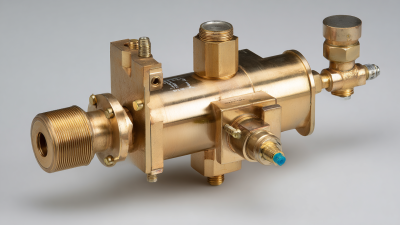

In industries such as food and beverage, pharmaceuticals, and chemical manufacturing, vacuum breaking valves ensure that vapor and air ingress are controlled effectively. This is vital not only for maintaining product quality but also for preventing hazardous conditions that could result from sudden vacuum loss. Data from a recent market survey indicates that approximately 60% of companies implementing vacuum breaking valves report a decrease in equipment malfunctions and a significant reduction in product loss due to contamination or spoilage.

Tip: Regular maintenance and testing of vacuum breaking valves are essential to ensure reliable performance. Scheduling periodic inspections can help identify potential wear and tear issues before they escalate, ultimately saving costs and preventing operational downtime.

Moreover, understanding the specific requirements of each industrial application can lead to optimal selection and placement of vacuum breaking valves. Detailed assessments can enhance system resilience, facilitating smoother operations while adhering to safety regulations. Tip: Consider consulting with engineering professionals to tailor the valve specifications to your system’s unique needs for maximum effectiveness.

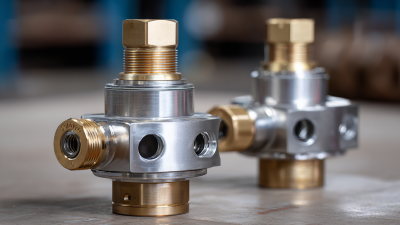

Vacuum breaking valves play a crucial role in maintaining system integrity across various industries. These specialized valves help prevent the formation of vacuum conditions that could lead to destructive stresses within pipelines and equipment. By allowing air to enter the system during a drop in pressure, vacuum breaking valves protect against potential collapse or damage, ensuring smooth operation and reliability. Their key functionality lies in their ability to monitor pressure levels and activate promptly to avoid issues associated with negative pressure.

Moreover, vacuum breaking valves contribute to safety and operational efficiency. By preventing the accumulation of vacuum pressure, they minimize the risk of implosions, which can pose significant safety hazards for personnel and infrastructure. These valves also enhance the life expectancy of the equipment by alleviating undue stress on pipes, tanks, and other components, ultimately reducing maintenance costs. In industries such as manufacturing, water treatment, and chemical processing, the integration of vacuum breaking valves is essential to uphold safety standards while ensuring continuous production flow.

Vacuum breaking valves play a crucial role in various industrial applications, contributing significantly to operational efficiency and safety. One of the primary benefits of implementing these valves is their ability to prevent the vacuum conditions that can lead to system failures. According to a report by the International Society of Automation, improper vacuum management can cause significant production downtimes, costing industries up to $10,000 per hour. By incorporating vacuum breaking valves, industries can mitigate these risks, ensuring consistent system performance and reducing the possibility of costly interruptions.

Moreover, vacuum breaking valves enhance the overall integrity of processing systems by allowing for controlled venting. This feature is particularly beneficial in industries such as food and beverage, pharmaceuticals, and chemicals, where product integrity is critical. The Global Market Insights report estimates that proper venting and pressure management can improve process yields by up to 15%. Implementing vacuum breaking valves not only helps in maintaining product quality but also aligns operations with health and safety regulations, ultimately leading to a more streamlined and compliant production environment.

Maintaining vacuum breaking valves is crucial for ensuring the efficient operation of various industrial systems. These valves play a critical role in preventing vacuum formation, which can lead to system failures or damage to equipment. One of the main challenges in maintaining these valves is the accumulation of debris and contaminants, which can hinder their performance. Regular inspection and cleaning of the valve components are essential to avoid operational disruptions.

To address maintenance challenges, it’s advisable to create a structured maintenance schedule. Implementing a detailed log of valve performance can help identify patterns or recurring issues, allowing for timely interventions. Additionally, using advanced monitoring technologies can facilitate real-time assessments, enabling quicker responses to potential failures.

Tips for effective vacuum breaking valve maintenance include conducting regular training for maintenance staff to familiarize them with the valve’s functionality and common issues. Moreover, ensuring that spare parts are readily available can significantly reduce downtime during repairs. Incorporating these practices into routine maintenance can extend the lifespan of vacuum breaking valves and enhance overall system reliability.

The future of vacuum breaking valve technology is poised for significant advancements as industries continue to prioritize efficiency and safety in their operations. Key trends indicate a growing emphasis on automation and smart technologies, which enable real-time monitoring and predictive maintenance.

As industries increasingly adopt Internet of Things (IoT) solutions, vacuum breaking valves will be integrated with advanced sensors to provide data about valve performance, helping operators detect issues before they escalate and ensuring systems function optimally. This shift not only enhances reliability but also minimizes downtime and maintenance costs.

Moreover, the push for sustainability is shaping innovations in vacuum breaking valve design and materials. Manufacturers are exploring eco-friendly materials to reduce the environmental footprint of these components while maintaining their durability and effectiveness. The implementation of energy-efficient designs, including reduced flow resistance and improved sealing mechanisms, will become more prevalent, aligning with global sustainability goals.

As industries move towards greener practices, vacuum breaking valves will play a critical role in maintaining operational efficiency without compromising environmental standards, thus supporting a more sustainable industrial future.