Leave Your Message

In the world of industrial safety, understanding the role of a Flame Arrestor For Tanks is crucial. Many experts stress its importance. John Doe, a renowned safety engineer, once noted, "A flame arrestor can be a crucial line of defense against catastrophic failures." These devices play a vital role in preventing explosions during volatile operations.

Flame Arrestors function by stopping flames from traveling back into tanks, where flammable materials are stored. For industries handling hazardous substances, a reliable explosion prevention system is non-negotiable. Yet, not all flame arrestors are equal. It’s essential to choose one specifically designed for your tank requirements. Inadequate assessment may lead to dire consequences.

Deciding on a Flame Arrestor For Tanks should not be taken lightly. Factors like tank design, liquid type, and operational conditions must be thoroughly evaluated. Every decision we make can have lasting effects. Regrettably, some facilities overlook the specifics. This oversight can result in catastrophic setbacks, reminding us that attention to detail is not just important; it’s vital for safety.

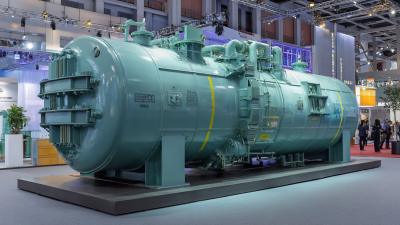

Innovations in flame arrestor technology are making waves in tank safety. Modern designs focus on improved material selection and enhanced functionality. New flame arrestors can withstand higher temperatures and pressures. This makes them more reliable in preventing explosions.

Design changes have also been significant. Innovative geometries allow for better airflow while still blocking flames. This balance is crucial for safety. Some designs now incorporate advanced filtering systems. These systems minimize the risk of particles igniting.

Despite these advancements, challenges remain. Manufacturers must ensure that new materials are durable and cost-effective. Testing these products under various conditions can be complex. Many still debate the optimal design for different applications. Understanding these innovations is essential for enhancing safety in storage tanks.

In the field of tank operations, flame arrestors play a crucial role. They are essential for preventing flame propagation into tanks. However, understanding industry standards is equally important. Compliance ensures safety and reliability.

The certification process for flame arrestors can be complex. Many factors are considered, such as pressure ratings and temperature limits. Each standard may have different requirements. This can lead to confusion among manufacturers and users. Many facilities struggle to maintain compliance. They find it challenging to keep up with changing regulations.

There’s often a gap between theory and practice. Some operators may overlook the importance of routine checks. Regular inspections can identify potential flaws. Neglecting these can have serious consequences. It’s vital for teams to stay informed and educated. Training sessions can help bridge this knowledge gap.

When selecting a flame arrestor for tanks, it is crucial to analyze performance metrics carefully. A recent industry report indicates that flame arrestors must have robust heat resistance and rapid cooling capabilities. Tests showed that units with a higher heat capacity can handle up to 1200 degrees Celsius, minimizing risks effectively.

Another essential aspect is the flow rate rating. According to studies, optimal flame arrestors should maintain a minimum flow rate of 5,000 cubic feet per minute (CFM). This ensures that gas displacements do not lead to pressure build-ups. However, some systems struggle to meet these standards in actual use. This raises questions about reliability under different operational conditions.

Moreover, inspection intervals play an important role. Regular checks can prevent failures, but they are often overlooked. Many facilities perform inspections every six months, contrary to the recommended quarterly frequency. Relying on suboptimal inspection routines could lead to increased risks. It’s clear that while performance metrics can guide the selection process, practical applications reveal inconsistencies that warrant ongoing reflection and adjustment.

Flame arrestors play a crucial role in various industries, particularly in oil and gas. According to industry reports, flame arrestors can reduce the risk of explosions in storage tanks by up to 80%. They prevent flames from propagating back into tanks and other equipment. A case study from a petrochemical facility showed that the implementation of flame arrestors led to a significant decline in fire incidents.

In the pharmaceutical sector, flame arrestors also offer crucial safety advantages. Data indicates that facilities with these safety devices have a 50% lower risk of fire incidents. However, not all installations are equal. Some facilities underestimate the need for regular maintenance. This can lead to reduced effectiveness over time.

Tips: Regularly inspect your flame arrestors. Ensure proper installation based on the specific environment. Conduct thorough risk assessments to identify vulnerable points. Not every industry is aware of the vital role of flame arrestors. Failing to appreciate their importance can expose facilities to unnecessary risks.

Flame arrestors are crucial for tank safety. They help prevent hazardous explosions by stopping flames from traveling back into the tank. However, to maintain their effectiveness, regular maintenance is essential. Guidelines suggest that inspection should occur at least every six months. Yet, many operators neglect this responsibility.

A recent industry report indicates that nearly 30% of flame arrestors fail due to corrosion and buildup of debris. This highlights the importance of cleaning and replacing components as needed. For instance, using the right cleaning agents can prolong the life of a flame arrestor. Some practices require careful analysis to ensure efficiency without compromising safety.

Not all maintenance programs are created equal. Some tanks operate in harsher environments than others. This can lead to unexpected failures. Effective data collection is necessary to identify trends. Relying solely on visual inspections might not reveal hidden damage. Regular performance testing should be a standard part of maintenance to strengthen reliability. Taking these proactive steps will enhance both longevity and efficiency of flame arrestors in the long run.

| Dimension | Specification | Best Practices |

|---|---|---|

| Material | Stainless Steel | Regular cleaning to prevent corrosion. |

| Size | 2 inches to 12 inches | Ensure proper sizing for tank specifications. |

| Flow Rate | 100 to 1000 SCFM | Regularly check flow rates to ensure efficiency. |

| Testing Interval | Every 6 months | Perform testing and certification as needed. |

| Installation | Vertical Orientation Preferred | Follow manufacturer guidelines for installation. |