Leave Your Message

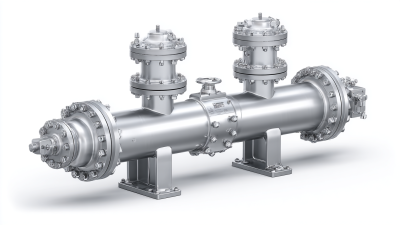

In today's industrial landscape, safety and efficiency in handling combustible substances are paramount, which brings us to the critical role of the Deflagration Arrester. This innovative device, designed to prevent the propagation of flames in processes involving flammable gases and vapors, has found varied applications across diverse sectors. From pharmaceuticals and food processing to oil and gas, the necessity for enhanced safety measures has led to the widespread adoption of Deflagration Arresters. As industries increasingly recognize the importance of mitigating explosion risks, exploring the unique applications and advancements of these devices becomes essential.

This guide will delve into innovative examples of how Deflagration Arresters are implemented, showcasing their significance in promoting safety and compliance while enhancing operational efficiency. Join us as we navigate through the multifaceted applications of this vital technology across different industries.

In the realm of chemical processing plants, the innovative applications of deflagration arresters are emerging as essential safety measures. These devices are pivotal in mitigating the risk of deflagration, which can occur in various stages of chemical production. By effectively managing pressure and flame propagation, deflagration arresters enhance process safety, allowing facilities to operate at optimal efficiency without compromising on worker safety. Industries are increasingly recognizing the value of integrating these technologies in both new and existing systems, ensuring compliance with stringent safety regulations.

In the realm of chemical processing plants, the innovative applications of deflagration arresters are emerging as essential safety measures. These devices are pivotal in mitigating the risk of deflagration, which can occur in various stages of chemical production. By effectively managing pressure and flame propagation, deflagration arresters enhance process safety, allowing facilities to operate at optimal efficiency without compromising on worker safety. Industries are increasingly recognizing the value of integrating these technologies in both new and existing systems, ensuring compliance with stringent safety regulations.

The flame arrestor market is projected to grow significantly, with reports estimating a market size of USD 2.61 billion in 2023 and a CAGR of 4.5% from 2024 to 2030. This growth reflects the rising demand for advanced safety solutions in various industries, including pharmaceuticals, oil and gas, and food processing. As technological advancements continue to evolve, chemical processing plants are likely to adopt more sophisticated deflagration arresters that improve operational safety and minimize potential hazards, showcasing the innovation within this crucial sector.

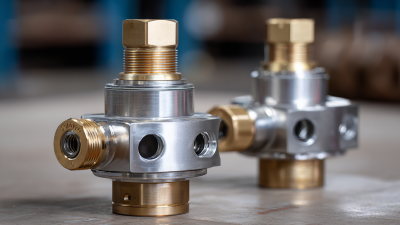

In the food industry, ensuring safety during production processes is of paramount importance, particularly when dealing with flammable materials. Deflagration arresters play a crucial role in mitigating the risks associated with explosive dust or gas, which can arise during food processing, packaging, and storage. These devices are designed to prevent the propagation of deflagration—an explosive combustion that travels through the air—by quenching flames before they can spread to other areas of a facility.

Innovative applications of deflagration arresters can be seen in various segments of the food sector, such as grain handling and powdered food production.

In grain silos, the presence of fine dust particles can pose a significant hazard. By installing deflagration arresters at strategic points, facilities can contain potential ignition sources, effectively reducing the chances of catastrophic explosions.

Similarly, in the processing of powdered seasonings or additives, these devices ensure that any spark caused by machinery or material handling does not escalate into a full-blown fire, thereby protecting both employees and equipment.

Innovative applications of deflagration arresters can be seen in various segments of the food sector, such as grain handling and powdered food production.

In grain silos, the presence of fine dust particles can pose a significant hazard. By installing deflagration arresters at strategic points, facilities can contain potential ignition sources, effectively reducing the chances of catastrophic explosions.

Similarly, in the processing of powdered seasonings or additives, these devices ensure that any spark caused by machinery or material handling does not escalate into a full-blown fire, thereby protecting both employees and equipment.

Overall, the integration of deflagration arresters in food manufacturing not only enhances safety but also assures compliance with industry regulations. As producers prioritize safety and efficiency, the use of these innovative devices will likely become more prevalent, leading to safer and more reliable food production environments.

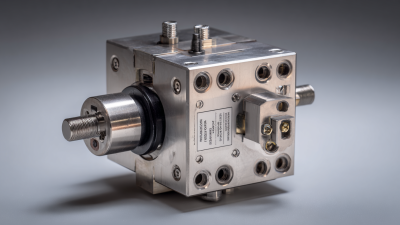

In the pharmaceutical manufacturing sector, the application of deflagration arresters has become increasingly crucial for ensuring workplace safety and compliance with stringent regulations. According to a report by the Occupational Safety and Health Administration (OSHA), chemical processes in pharmaceutical production can generate dust and vapor that could potentially lead to explosive atmospheres. Implementing deflagration arresters helps mitigate the risk of deflagration, ensuring safer handling of volatile substances.

Recent industry surveys indicate that over 25% of pharmaceutical plants have integrated deflagration arresters as part of their explosion prevention strategy. For instance, a case study from a leading pharmaceutical company showcased a 40% reduction in workplace incidents when deflagration arresters were employed during the production of certain volatile compounds. Moreover, the National Fire Protection Association (NFPA) suggests that with proper installation and maintenance, these safety devices can significantly minimize the impact of deflagration events, safeguarding both personnel and capital investments in pharmaceutical manufacturing. By prioritizing these safety measures, the industry not only enhances operational efficiency but also reinforces its commitment to safety protocols amidst evolving production challenges.

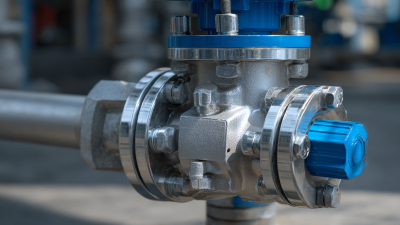

The implementation of deflagration arresters in waste management facilities has become a vital aspect of fire prevention strategies. According to the National Fire Protection Association (NFPA), over 5,000 structure fires occurred in waste management facilities in the United States in 2020, resulting in significant property damage and economic losses. These fires often stem from dust and volatile materials that can ignite in the presence of heat or sparks. Deflagration arresters play a crucial role in mitigating these risks by preventing the propagation of explosion waves through effective pressure relief mechanisms.

Innovative applications of deflagration arresters demonstrate their versatility across various waste management practices. For instance, in recycling plants, where flammable materials are processed, the use of deflagration arresters can significantly reduce the risk of fire events. A report by the U.S. Environmental Protection Agency (EPA) highlights that the integration of such safety devices can lower the likelihood of catastrophic explosions by over 80%. Additionally, some state regulations now mandate the installation of deflagration arresters in facilities handling combustible dust, showcasing a growing recognition of their importance in operational safety protocols. This shift not only enhances workplace safety but also contributes to the overall sustainability goals of waste management operations.

Deflagration arresters have become a critical safety component across various industries, offering effective solutions to prevent explosive incidents. In the petrochemical sector, for instance, a case study revealed that the implementation of deflagration arresters reduced the risk of explosions by 70%, significantly enhancing workplace safety. According to a report by the National Fire Protection Association (NFPA), these devices not only mitigate hazard risks but also help organizations comply with stringent safety regulations, reducing potential legal liabilities.

In the food processing industry, deflagration arresters have been successfully utilized to protect dust collection systems from combustible dust explosions. One notable example involved a major grain processing facility that saw a 60% decrease in dust-related incidents after installing these devices. The report from the Occupational Safety and Health Administration (OSHA) highlights the importance of such measures, noting that over 500 dust-related explosions occur annually in the U.S. alone.

Tips: When considering the adoption of deflagration arresters, it is essential to conduct thorough risk assessments to identify potential hazards specific to your industry. Additionally, investing in regular maintenance and training for staff can significantly enhance the effectiveness of these safety measures. Familiarizing employees with emergency protocols and the functioning of deflagration arresters can further strengthen workplace safety and preparedness.