Leave Your Message

In today's competitive industrial landscape, the efficiency of operational processes is paramount. One pivotal component that significantly influences performance is the Pilot Operated Diaphragm Valve (PODV). According to a recent report by Research and Markets, the global valve market is projected to reach $85 billion by 2025, with diaphragm valves, particularly pilot-operated variants, witnessing substantial growth due to their superior control capabilities and reliability. The ability to handle varied pressure conditions and provide precise flow regulation makes PODVs an essential choice across numerous industries, including water treatment, chemical processing, and pharmaceuticals. As companies continually seek to optimize production methods and reduce downtime, adopting the best Pilot Operated Diaphragm Valve can undeniably transform operations, ensuring higher efficiency and cost-effectiveness. This blog will explore five compelling reasons why incorporating PODVs into your system can lead to remarkable operational improvements.

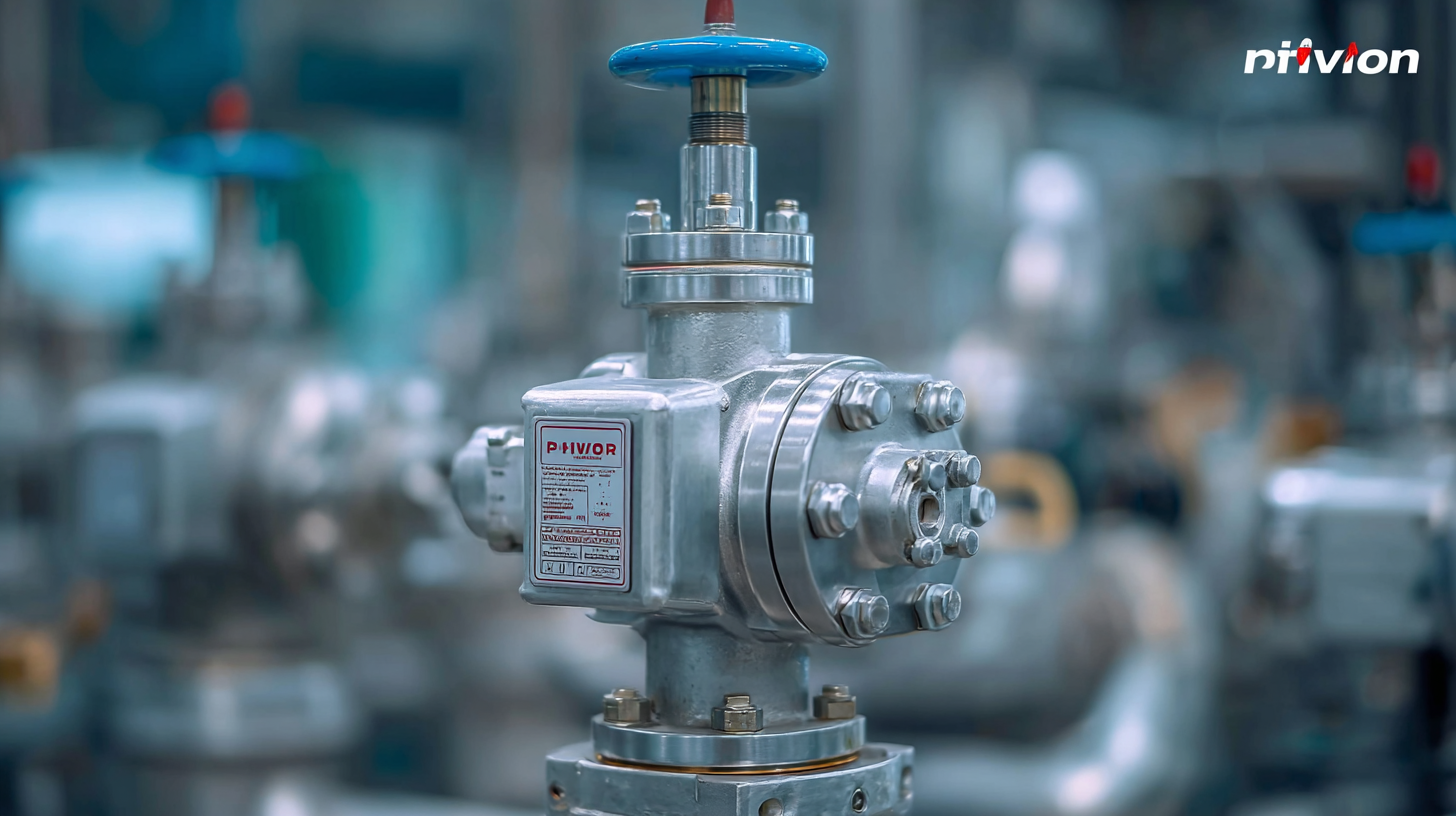

Pilot operated diaphragm valves are revolutionizing the way industries manage fluid control. By harnessing the principles of pressure regulation, these valves offer a significant boost in efficiency, enabling operations to run smoother and faster. The unique design allows for quick response times and precise flow control, minimizing downtime and ensuring that processes continue without interruption. This dynamic response means less time spent on maintenance and troubleshooting, which ultimately translates to substantial time savings.

Moreover, pilot operated diaphragm valves contribute to resource conservation by optimizing fluid use. Their ability to maintain consistent pressure reduces waste, allowing companies to operate more sustainably while also lowering operational costs. With advanced materials and innovative design, these valves ensure enhanced durability and reliability, further decreasing the need for replacements or repairs. As a result, businesses can redirect their resources towards growth and development, unlocking new avenues of productivity. In this way, adopting pilot operated diaphragm valves not only enhances operational efficiency but also reinforces a company's commitment to sustainable practices.

In the realm of fluid control systems, the significance of precision cannot be overstated. According to a recent report by Research and Markets, the global market for diaphragm valves is expected to grow significantly, driven by the demand for greater accuracy and control in industrial applications.

Pilot-operated diaphragm valves offer exceptional advantages that can elevate operational efficiency. They provide superior leak prevention and adjustability, enabling operators to fine-tune flow rates with remarkable accuracy. This level of control directly influences product quality and operational costs, making it an indispensable choice for industries ranging from pharmaceuticals to food processing.

Pilot-operated diaphragm valves offer exceptional advantages that can elevate operational efficiency. They provide superior leak prevention and adjustability, enabling operators to fine-tune flow rates with remarkable accuracy. This level of control directly influences product quality and operational costs, making it an indispensable choice for industries ranging from pharmaceuticals to food processing.

Moreover, a study conducted by the Flow Control Institute indicates that industries utilizing advanced diaphragm valves have reported a notable decrease in fluid discrepancy by up to 30%. This reduction not only enhances precision but also contributes to sustainable practices by minimizing waste. The ability to maintain consistent pressure and flow ensures that systems operate optimally, reducing energy consumption and prolonging equipment lifespan. As industries strive for improved process control, investing in the best pilot-operated diaphragm valves emerges as a transformative step towards attaining operational excellence.

Pilot operated diaphragm valves have emerged as a game-changer in various industrial applications, particularly in high-demand environments such as mining where downtime can significantly impact productivity. Their reliability is a crucial selling point; according to a recent industry report, valves that offer enhanced reliability can reduce equipment failures by up to 30%. This translates directly into reduced operational interruptions, allowing for smoother workflow and increased output.

The introduction of advanced slurry management solutions, such as air release valves designed for performance, further underscores the significant improvements in operational reliability. These new technologies are engineered to handle the challenges posed by corrosive and abrasive slurries, which are prevalent in mining operations. Studies indicate that improper management of slurry can lead to a staggering 20% increase in maintenance costs due to frequent repairs and replacements. By utilizing top-tier pilot operated diaphragm valves, operations can ensure consistent performance and longevity, thereby minimizing unexpected downtimes and enhancing overall efficiency.

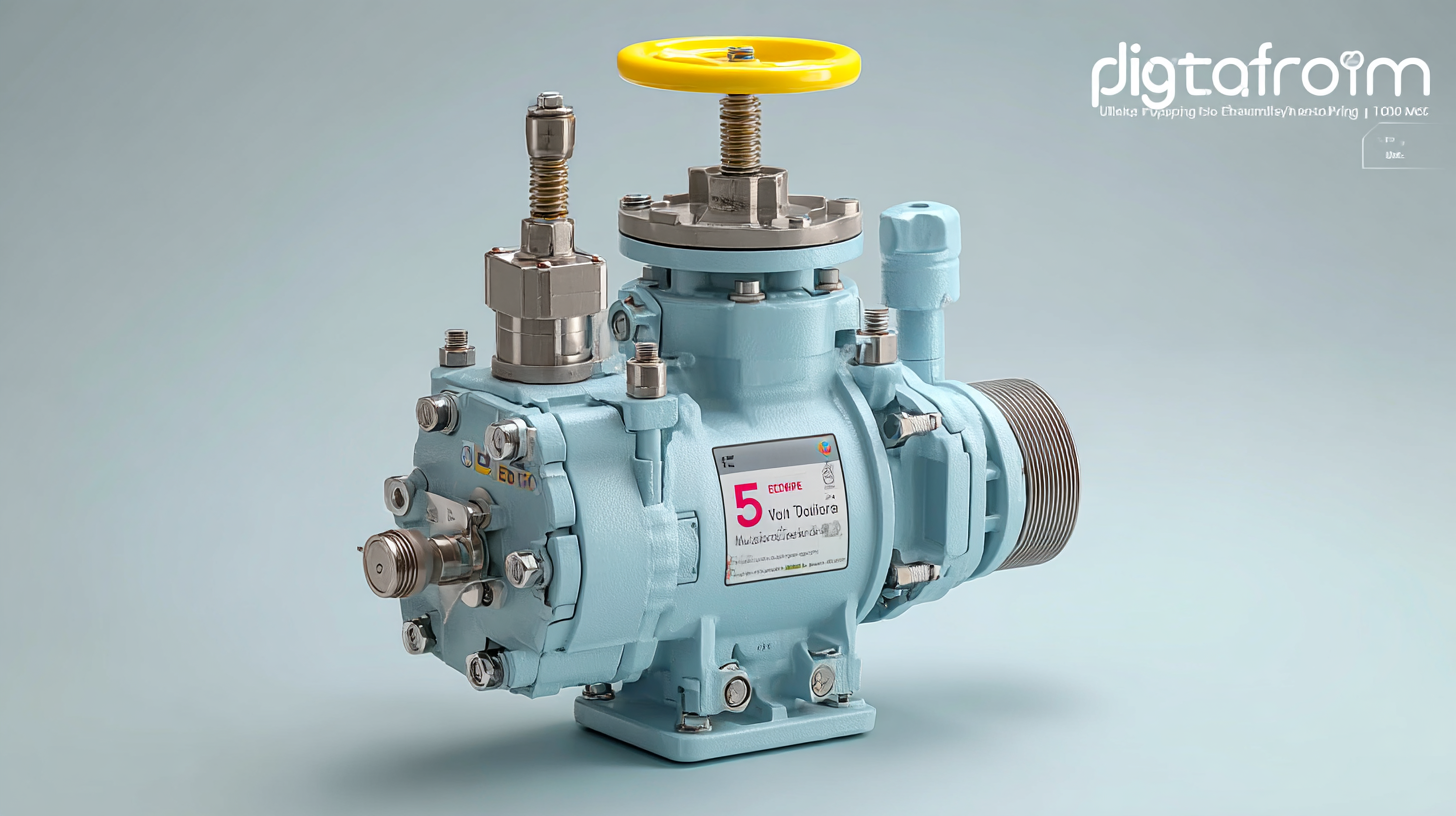

When considering operational efficiency, the choice of diaphragm valves can significantly impact both performance and costs. A pilot-operated diaphragm valve, specifically designed for durability and efficiency, can lead to substantial long-term savings. These valves are built to withstand harsh environments and frequent usage, minimizing the need for replacements and reducing downtime caused by equipment failure. The investment in high-quality valves pays off as they require less maintenance, leading to decreased operational interruptions and more consistent output.

Additionally, cost-effective valve solutions foster improved system performance. By ensuring optimal flow control, these diaphragm valves help in reducing energy consumption and resource wastage. Their precise operation means that processes run more smoothly and efficiently, enhancing overall productivity. Ultimately, selecting the right pilot-operated diaphragm valve is not just about the immediate cost; it’s about the long-term operational benefits that can transform your operations by supporting sustainable practices and maximizing your return on investment.

This bar chart illustrates the cost impact of transitioning to pilot operated diaphragm valves. The data shows initial costs, maintenance expenses, operational efficiency contributions, long-term savings, and costs associated with downtime. Investing in durable valves can lead to substantial savings over time.

Modern diaphragm valves have revolutionized operational efficiency by simplifying maintenance with user-friendly features. One of the standout characteristics of these valves is their easy access design. Unlike traditional valves that require extensive disassembly for inspection or repairs, modern diaphragm valves often allow for quick access to the diaphragm and other internal components. This significantly reduces downtime, enabling operators to conduct routine maintenance with minimal disruption to their workflows.

Tip: Regularly check the diaphragm and replace it if signs of wear are evident. This proactive approach not only extends the valve's lifespan but also ensures optimal performance.

Another key feature is the integration of visual indicators that provide real-time feedback on valve status. These indicators help operators quickly identify issues, allowing for swift action to be taken. Enhanced diagnostics can prevent escalated problems, ensuring that operations continue smoothly and efficiently.

Tip: Take advantage of digital monitoring tools available with some modern diaphragm valves. These systems can send alerts for maintenance needs, further simplifying the oversight of your valve operations.