Leave Your Message

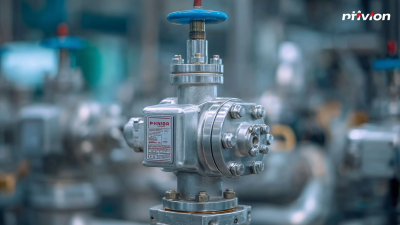

Choosing the right Blanket Gas Regulator for your industrial applications is critical for optimizing operational efficiency and ensuring safety standards. According to the latest report from the Gas Safety and Regulation Authority, nearly 30% of industrial incidents are linked to improper gas flow management, highlighting the importance of selecting the appropriate gas regulator. A Blanket Gas Regulator is designed to maintain a constant pressure in gas storage systems, significantly affecting product quality and performance in various sectors, including pharmaceuticals, food processing, and petrochemicals.

Choosing the right Blanket Gas Regulator for your industrial applications is critical for optimizing operational efficiency and ensuring safety standards. According to the latest report from the Gas Safety and Regulation Authority, nearly 30% of industrial incidents are linked to improper gas flow management, highlighting the importance of selecting the appropriate gas regulator. A Blanket Gas Regulator is designed to maintain a constant pressure in gas storage systems, significantly affecting product quality and performance in various sectors, including pharmaceuticals, food processing, and petrochemicals.

With the global industrial gas regulator market projected to reach USD 4.2 billion by 2026, choosing the right model becomes paramount for operational excellence and compliance with stringent safety regulations. This guide will delve into the essential factors to consider when selecting a Blanket Gas Regulator that meets your operational needs.

Choosing the right blanket gas regulator for industrial applications requires a deep understanding of specific operational needs and regulatory standards. One of the key considerations is the flow rate, which is vital for maintaining consistent pressure across various processes. According to a report by the Industrial Gas Association, improper flow rates can lead to inefficiencies, resulting in losses of up to 15% in production processes. Therefore, it is crucial to select regulators that can handle the required flow rates without causing pressure fluctuations.

Another significant factor is the compatibility of the blanket gas regulator with the type of gas used. Different gases exert different pressures and require distinct materials for safe handling. A recent study published by the Compressed Gas Association indicated that using inappropriate materials can lead to equipment failures or hazardous leaks, impacting both safety and compliance. It's essential to ensure that the selected regulator is designed for the specific gas being used, taking into account factors like temperature and pressure conditions. By prioritizing flow rates and compatibility, organizations can enhance efficiency and safety in their industrial operations.

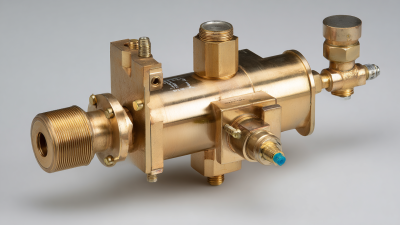

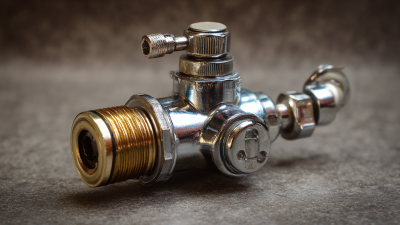

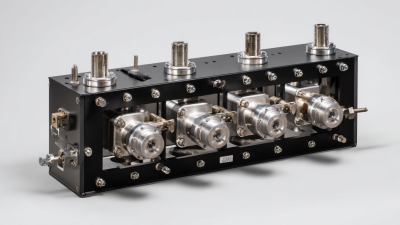

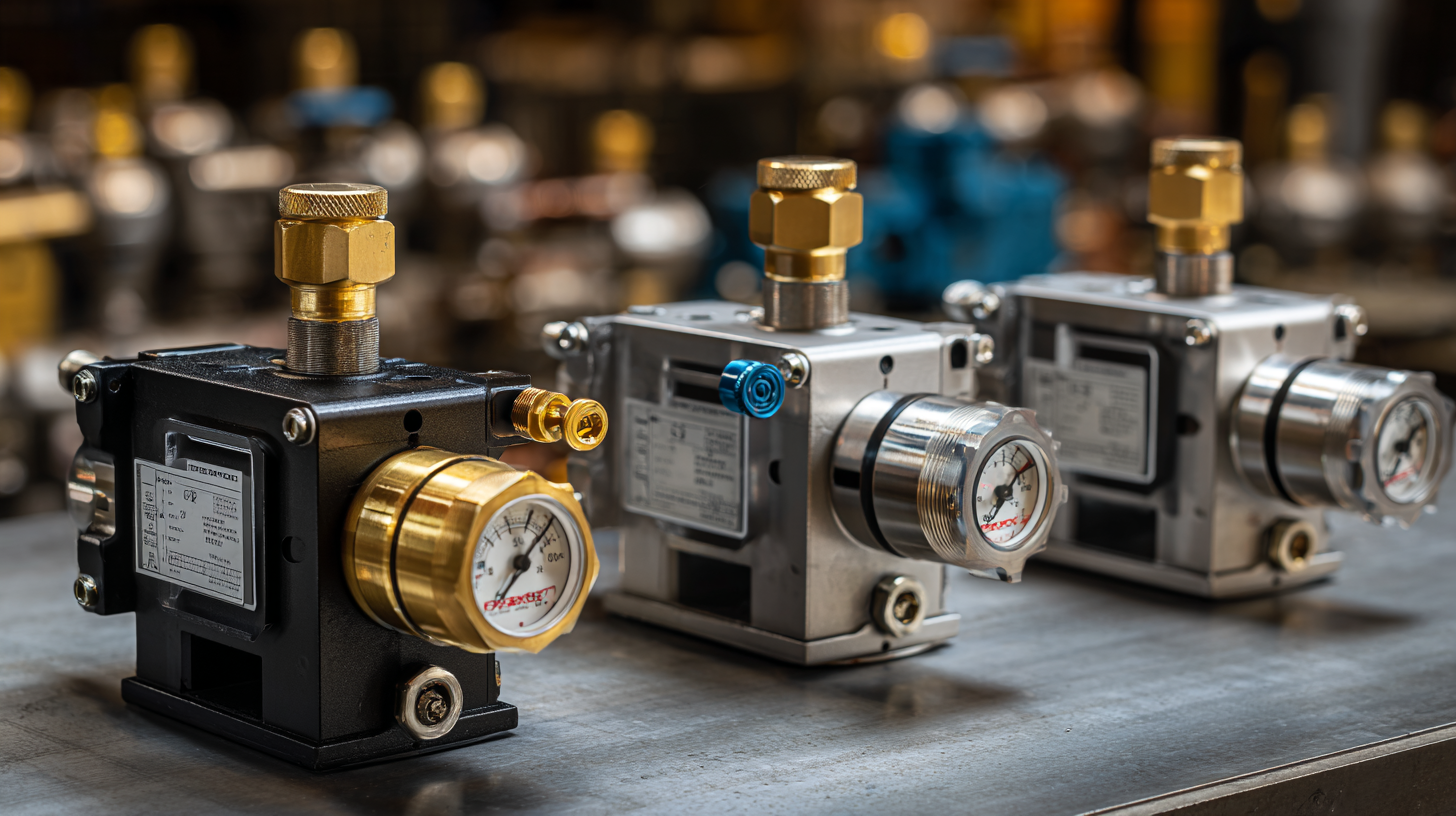

When it comes to selecting the right blanket gas regulator for industrial applications, it is essential to understand the various types available in the market. Blanket gas regulators are critical in maintaining consistent gas pressure in processes such as storage or transportation of liquids and gases. They help ensure safety and efficiency, particularly in industries like petrochemicals, where precise control over gas supply is crucial.

There are primarily three types of blanket gas regulators: single-stage, dual-stage, and high-pressure regulators. According to industry reports, single-stage regulators are ideal for low-pressure applications, providing quick adjustments; however, they may not ensure consistent pressure over longer time periods. In contrast, dual-stage regulators maintain a more stable pressure as the supply decreases, making them suitable for varying demand scenarios. High-pressure regulators are designed for applications requiring higher flow rates and can address the complexities of industrial processes effectively.

Recent trends indicate a growing preference for dual-stage regulators in sectors aiming to enhance operational efficiency. Data from market analysis shows that the demand for highly reliable blanket gas regulators is expected to increase by 25% over the next five years. This highlights the importance for companies to assess their specific industrial needs, as selecting the appropriate type of blanket gas regulator can have significant implications on both safety and operational efficiency.

When selecting a blanket gas regulator for industrial applications, several key features should be prioritized to ensure optimal performance and safety. First, look for pressure control precision. A high-quality regulator should provide consistent pressure output, minimizing fluctuations that could disrupt processes or lead to safety hazards. Additionally, the regulator's ability to respond quickly to changes in demand is vital; therefore, choose a model that offers rapid adjustments to maintain stable pressure levels.

Durability is another crucial aspect when assessing blanket gas regulators. These devices are often exposed to harsh industrial environments, so selecting a robust unit made from high-grade materials can enhance longevity and decrease maintenance costs. Furthermore, consider the flow capacity of the regulator, as this determines its efficiency in handling various gas volumes. A model with a known track record of reliability in similar applications will be beneficial, as reputation can often indicate the regulator's overall quality and performance.

| Feature | Description | Importance |

|---|---|---|

| Pressure Control | Ability to maintain consistent gas pressure. | Critical for safety and process efficiency. |

| Material Quality | Use of corrosion-resistant materials. | Enhances durability and lifespan. |

| Flow Capacity | Maximum gas flow rate it can handle. | Ensures sufficient supply for operations. |

| Temperature Range | Operational temperature limits of the regulator. | Needed for diverse environmental conditions. |

| Safety Features | Inbuilt safety mechanisms (e.g., pressure relief). | Prevents accidents and enhances safety. |

| Ease of Maintenance | Design that allows for simple servicing and repairs. | Reduces downtime and maintenance costs. |

When selecting a blanket gas regulator for industrial applications, avoiding common pitfalls is crucial to ensuring optimal functionality and safety. One prevalent mistake is underestimating the pressure requirements of the specific application. According to a report by the American Gas Association, improper pressure settings can lead to inefficient gas flow, compromising production efficiency by up to 20%. It is vital to accurately assess the minimum and maximum pressure needs and to adjust the specifications of the regulator accordingly.

Another common error is neglecting to consider the material compatibility of the blanket gas regulator with the gases being used. Many industrial gases can react differently with materials, which can lead to malfunctions or safety hazards. The Industrial Gas Association indicates that a significant portion of equipment failures is due to incompatible materials, emphasizing the importance of choosing regulators made from materials specifically designed to withstand the operational conditions of the gas involved. Careful evaluation of these factors can prevent costly downtimes and enhance safety in industrial settings.

When maintaining a blanket gas regulator, optimal performance hinges on regular inspections and timely interventions. It’s essential to check for any leaks and ensure all connections are secure. A thorough cleaning of the regulator can prevent buildup of residue that may impact its efficiency. Additionally, monitoring the gas pressure regularly can help detect any irregularities early, allowing for timely adjustments.

Tips for maintaining your blanket gas regulator include performing routine checks on the inlet and outlet pressure gauges to ensure they are functioning correctly. If you notice fluctuations in gas flow or pressure, it might be time to replace certain components. Furthermore, consider the environmental conditions in which the regulator operates; extreme temperatures can affect performance. Keeping the regulator insulated can help maintain consistent performance levels.

For those involved in industrial applications, understanding the implications of different blanket gas materials and configurations is crucial. Regularly consulting with experts in blanket gas technology can provide insights into best practices for your specific setup, enhancing overall system efficiency and longevity.