Leave Your Message

In industrial settings where flammable gases and vapors are handled, ensuring safety and preventing explosions is paramount. One crucial component in achieving this is the use of Deflagration Type Flame Arresters. These devices serve as a protective barrier, effectively stopping flame propagation through the gas or vapor mixture in pipelines and storage systems.

This introduction aims to explore the effective utilization of Deflagration Type Flame Arresters, highlighting their design, functionality, and application in various industrial processes. By understanding the principles behind these flame arresters, businesses can enhance their safety protocols, mitigate risks associated with combustible materials, and comply with regulatory standards.

With the right implementation and maintenance strategies, Deflagration Type Flame Arresters can significantly contribute to a safer working environment, ensuring the longevity of equipment and safeguarding human lives.

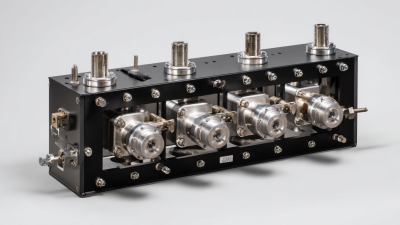

Deflagration type flame arresters are critical safety devices used in various industrial settings to prevent the propagation of flame through pipelines and vessels. These devices operate based on the principle of reducing the speed of a deflagration, which is a subsonic combustion process. The National Fire Protection Association (NFPA) reports that flame arresters can effectively reduce the risk of explosion in industries handling flammable gases and vapors. It is estimated that proper implementation of these devices can lower the occurrence of incidents by up to 70%, thereby enhancing workplace safety and operational efficiency.

In industrial applications, selecting the right type of flame arrester is vital. For instance, data from the American Petroleum Institute (API) indicates that in facilities processing volatile compounds, deflagration flame arresters can potentially save millions in damage costs annually by mitigating explosion risks. Furthermore, the usage of these devices is not limited to petroleum applications; they are also found in chemical manufacturing, waste treatment facilities, and food processing plants. Understanding the key principles of deflagration flame arresters, such as their design features and materials used, is essential for engineers and safety professionals to ensure compliance with safety regulations and to maximize their effectiveness in preventing catastrophic events.

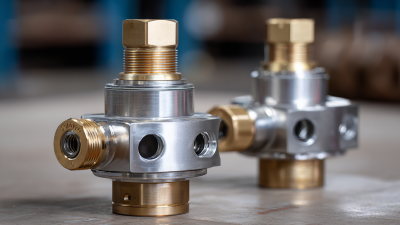

When selecting the right deflagration flame arresters for specific industrial processes, it is crucial to understand the operational environment and the characteristics of the substances involved. Different industries handle various flammable gases and vapors, each requiring distinct flame arrester specifications. For example, in the chemical manufacturing sector, where volatile compounds are prevalent, using devices that cater to specific ignitability thresholds is essential for maintaining safety. Proper selection ensures that the arresters provide optimal protection against flame propagation while minimizing pressure drop and flow resistance.

Moreover, considerations such as temperature, pressure, and the physical layout of the system play vital roles in determining the suitability of a flame arrester. Factors like the distance from potential ignition sources and the configuration of pipelines can influence the arrester's effectiveness. Industry professionals must also adhere to relevant standards and certifications when selecting these safety devices. By carefully evaluating these parameters and conducting thorough risk assessments, companies can ensure that they implement the most effective deflagration flame arresters tailored to their unique industrial processes, thereby enhancing overall safety and operational efficiency.

Effectively utilizing deflagration type flame arresters in industrial settings is crucial for ensuring safety and operational efficiency. To maximize the efficiency of these devices, proper installation is key. Begin by assessing the specific requirements of your facility and the potential hazards associated with flammable gases or vapors. It's important to choose the right type and size of flame arrester that aligns with the flow rates and the characteristics of the materials being handled.

**Tips:** Ensure that the flame arrester is installed in a location that allows for proper ventilation and is free from obstructions. Regularly check and maintain the flame arresters as part of your safety protocol to ensure their functionality. Avoid installing arresters too close to bends or valves, as this might disrupt airflow and impede effectiveness.

Additionally, consider the orientation during installation. While horizontal installations are common, vertical arrangements may be preferable in certain applications to manage liquid accumulation. It's vital to follow the manufacturer’s guidelines closely to ensure compliance with safety regulations, which ultimately minimizes the risk of fire incidents in your facility.

In industrial settings, ensuring the functionality of deflagration type flame arresters is crucial for fire safety. Regular maintenance and inspection protocols are essential to prevent dangerous incidents. These arresters must be checked routinely to ascertain that they are free from blockages and damage, which can compromise their effectiveness. Inspecting gasket integrity and ensuring that the arresters meet industry standards are also critical steps that can significantly enhance safety.

Tips for Maintenance:

In the context of rooftop solar power plants, incorporating flame arresters into the safety architecture is equally vital. As these facilities become increasingly common, understanding fire safety measures remains paramount. Regular checks of flame arresters, alongside comprehensive training for personnel on emergency procedures, can significantly mitigate risks associated with solar installations. Prioritizing fire safety not only protects lives but also ensures the longevity of these renewable energy systems.

In the context of fire safety in industrial settings, compliance with industry standards and regulations for flame arresters is paramount. Deflagration type flame arresters play a critical role in preventing fire hazards associated with flammable substances. Their design and functionality must align strictly with regulatory requirements to ensure reliable performance in real-world applications. The recent mandate by the U.S. Consumer Product Safety Commission (CPSC) requiring safety devices in consumer containers for flammable liquids underscores the importance of incorporating efficient flame mitigation technologies in all relevant applications.

The construction industry can learn significant lessons from past incidents, emphasizing the need for stringent adherence to safety protocols. Innovations such as advanced flame arresters have made it possible to enhance safety and environmental reliability within industrial practices. By proactively implementing effective flame arresters, companies can not only comply with regulations but also contribute to a culture of safety that protects both personnel and property from potential fire-related risks.

| Dimension | Data |

|---|---|

| Typical Applications | Chemical processing, petroleum industries, grain silos |

| Applicable Standards | NFPA 68, EN 12874, ISO 16852 |

| Installation Location | Near potential ignition sources, discharge points of combustible gases |

| Maintenance Frequency | Every 6 months |

| Key Performance Indicators | Pressure drop, reaction time, material integrity |

| Common Materials | Stainless steel, aluminum, carbon steel |

| Performance Testing Standards | ISO 16852, UL 525 |

| Training Requirements | Annual training on operation and safety |