Leave Your Message

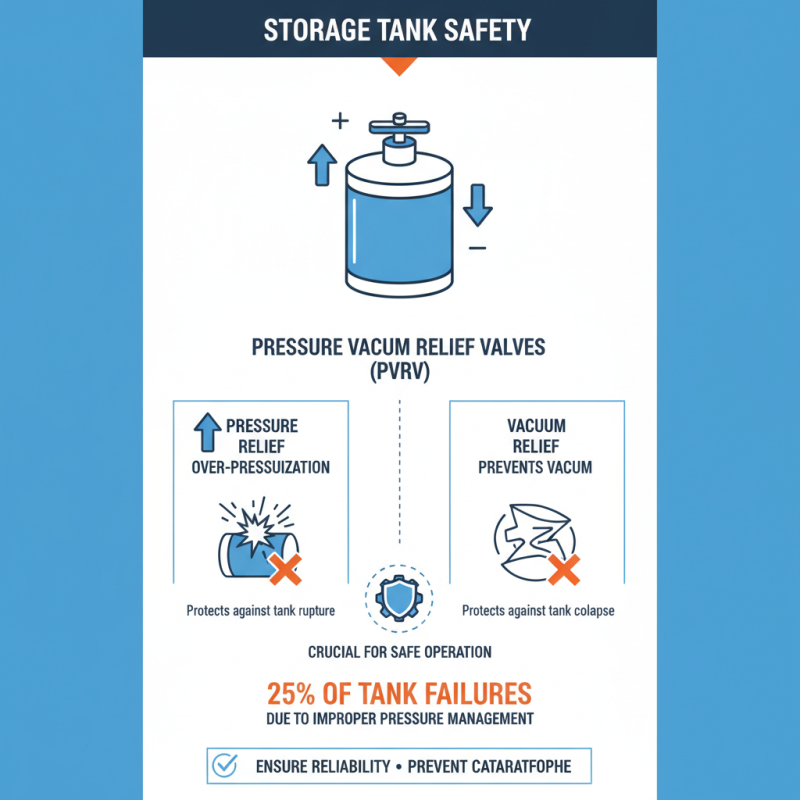

In the world of storage tanks, the Pressure Vacuum Relief Valve plays a critical role in safety and efficiency. According to John Smith, a leading expert in tank safety, “A well-functioning Pressure Vacuum Relief Valve is the heartbeat of any tank system.” This statement highlights its importance in preventing catastrophic failures.

The Pressure Vacuum Relief Valve is designed to manage changes in pressure within storage tanks. Without it, dangerous situations can arise. For example, over-pressurization can lead to explosions, while excessive vacuum can cause structural collapse. Knowing this, operators must prioritize the regular maintenance of these valves.

However, not all operators fully understand their significance. In some cases, these valves are overlooked during inspections. This can lead to regrettable incidents. It’s essential for industry professionals to recognize that the Pressure Vacuum Relief Valve isn’t just an accessory; it's a lifeline for storage tank operations. Every tank owner should ensure these valves are functioning properly to avoid potential disasters.

Pressure vacuum relief valves (PVRVs) play a critical role in storage tank systems. They are designed to handle pressure fluctuations and prevent tank collapse during liquid transfer. According to the American Petroleum Institute, improper tank pressure management can lead to significant safety hazards. In fact, over 70% of tank incidents result from pressure-related failures.

These valves ensure that tanks maintain a balanced pressure. When a tank is filled, the valve opens, allowing air in. Conversely, during emptying, it releases excess pressure. A study by the National Fire Protection Association indicates that tanks equipped with PVRVs experience 30% fewer incidents. This underscores the importance of these safety devices.

The installation of PVRVs can be overlooked. Many facilities operate without them, taking unnecessary risks. Some may argue that current systems are sufficient. However, data suggests that even minor pressure changes can impact tank integrity. Regular maintenance is essential, yet often neglected. This raises questions about industry practices and safety priorities. Every tank deserves the protection that a reliable valve provides.

| Aspect | Description | Importance |

|---|---|---|

| Pressure Management | Regulates pressure within the tank to prevent overpressure and vacuum conditions. | Prevents tank damage and potential leaks. |

| Safety | Mitigates hazards associated with fire and explosion due to excessive pressure. | Enhances overall operational safety. |

| Environmental Protection | Limits emissions and possible leakage of hazardous materials into the environment. | Protects surroundings and complies with environmental regulations. |

| Operational Efficiency | Ensures consistent flow and pressure levels during operation. | Improves productivity and reliability of the storage system. |

| Maintenance | Facilitates easier maintenance checks by providing visual pressure indicators. | Simplifies management of tank system integrity. |

Pressure vacuum relief valves (PVRVs) are crucial for storage tanks. They maintain the balance of pressure and vacuum, preventing catastrophic failures. According to the NFPA (National Fire Protection Association), almost 30% of storage tank incidents are due to improper venting. This highlights the importance of PVRVs in protecting both the tank and its contents.

These valves operate by allowing air into the tank when internal pressure drops, or releasing vapor when pressure builds. This functionality helps prevent tank collapse and spillage. The API (American Petroleum Institute) recommends regular inspections of PVRVs to ensure they operate effectively. Many facilities fail to perform these checks. This negligence can lead to significant risks.

Tips: Conduct routine maintenance on PVRVs to avoid unexpected failures. Regular checks can save you from costly repairs. Remember, a small oversight can lead to major issues.

In some cases, PVRVs may malfunction. Debris or corrosion can obstruct proper operation. This is why monitoring tank conditions is essential. Ignoring these factors can lead to terminal consequences. Ensure your team understands these vulnerabilities to create a safer storage environment.

Pressure vacuum relief valves (PVRVs) play a crucial role in the safe operation of storage tanks. These valves help manage pressure changes during filling and emptying processes. They ensure that the tank does not build up excessive pressure or vacuum, which can lead to structural failures. According to recent industry reports, improper pressure management can result in up to 25% of storage tank failures. This highlights the significance of utilizing PVRVs.

PVRVs provide several key benefits. They protect the tank from collapse during vacuum conditions. Additionally, they prevent the release of harmful vapors, contributing to environmental safety. Data indicates that tanks equipped with PVRVs experience fewer incidents of failure and leakage. In fact, using these valves can improve operational efficiency by up to 30%. Regular maintenance is also necessary. A stuck valve can lead to costly repairs and downtime.

**Tip:** Always inspect your PVRVs regularly. Check for signs of wear and tear. Ensure that they open and close properly. A small issue can escalate quickly.

PVRVs are essential for maintaining the integrity of storage tanks. However, operators often overlook their importance. Neglecting these valves can cause serious problems. Therefore, staying informed and vigilant is key to safe storage tank management. Don't wait for a failure to occur before addressing these critical components.

Pressure vacuum relief valves (PVRVs) play a critical role in various industries. For instance, in the chemical sector, these valves prevent structural failures by maintaining atmospheric pressure in storage tanks. In a recent industry report, it was noted that improper pressure management during liquid transfer could lead to tank rupture. Such failures can result in the loss of product and environmental hazards.

Oil and gas operations also significantly benefit from PVRVs. These valves help manage the pressure from vapor build-up and liquid changes during transport. Data shows that nearly 20% of incidents involving storage tanks arise from inadequate pressure management. For example, when the temperature rises, vapor pressure increases inside a tank. A PVRV helps normalize this pressure.

In the food and beverage industry, these valves are essential for safety. They ensure that tanks do not collapse or explode from negative pressure. Clear data indicates that 15% of food processing safety incidents are linked to pressure issues. Without PVRVs, the risk of contamination or loss of product integrity increases. It raises important considerations about maintenance and operational standards.

Pressure vacuum relief valves (PVRVs) play a crucial role in maintaining the safety and integrity of storage tanks. Regular maintenance of these valves is essential. A malfunctioning valve can lead to catastrophic tank failures. According to industry reports, approximately 20% of storage tank incidents are linked to improper management of these valves. This statistic highlights the importance of keeping PVRVs in good working condition.

To ensure the valves are functioning properly, routine inspections should be conducted. Checking for wear and tear is vital. Additionally, testing the valves under different pressures can reveal hidden issues. A minor defect can escalate quickly, resulting in dangerous conditions. Implement a maintenance schedule that adheres to industry standards. This could significantly reduce the risk of accidents.

Tips: Always keep replacement parts ready. This can save precious time during emergencies. Educate your team about the operating principles of PVRVs. A well-informed team can make better decisions. Regular training sessions can enhance safety protocols. Remember, safety should always be the primary focus.