Leave Your Message

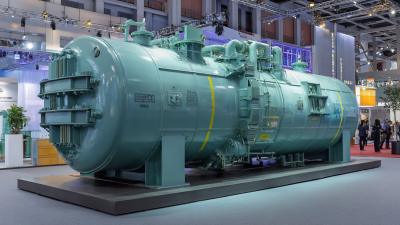

In the world of gas management, selecting the right Blanket Gas Regulator is crucial for ensuring safety, efficiency, and optimal performance in various applications. According to a recent industry report by MarketsandMarkets, the global market for gas regulators is expected to reach USD 6.5 billion by 2026, growing at a CAGR of 6.2% from 2021. This surge reflects the increasing demand for precise gas control in industries ranging from healthcare to manufacturing. A Blanket Gas Regulator serves a vital function by maintaining a constant, pre-set pressure of gas within a system, thereby preventing fluctuations that can damage equipment or compromise safety. The importance of choosing the correct type cannot be overstated, as improper regulator selection can lead to operational inefficiencies and increased costs. Whether for storage tanks, pipelines, or manufacturing processes, understanding the key factors in selecting a Blanket Gas Regulator tailored to specific needs is essential for achieving reliable gas management solutions.

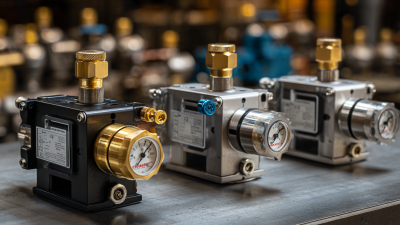

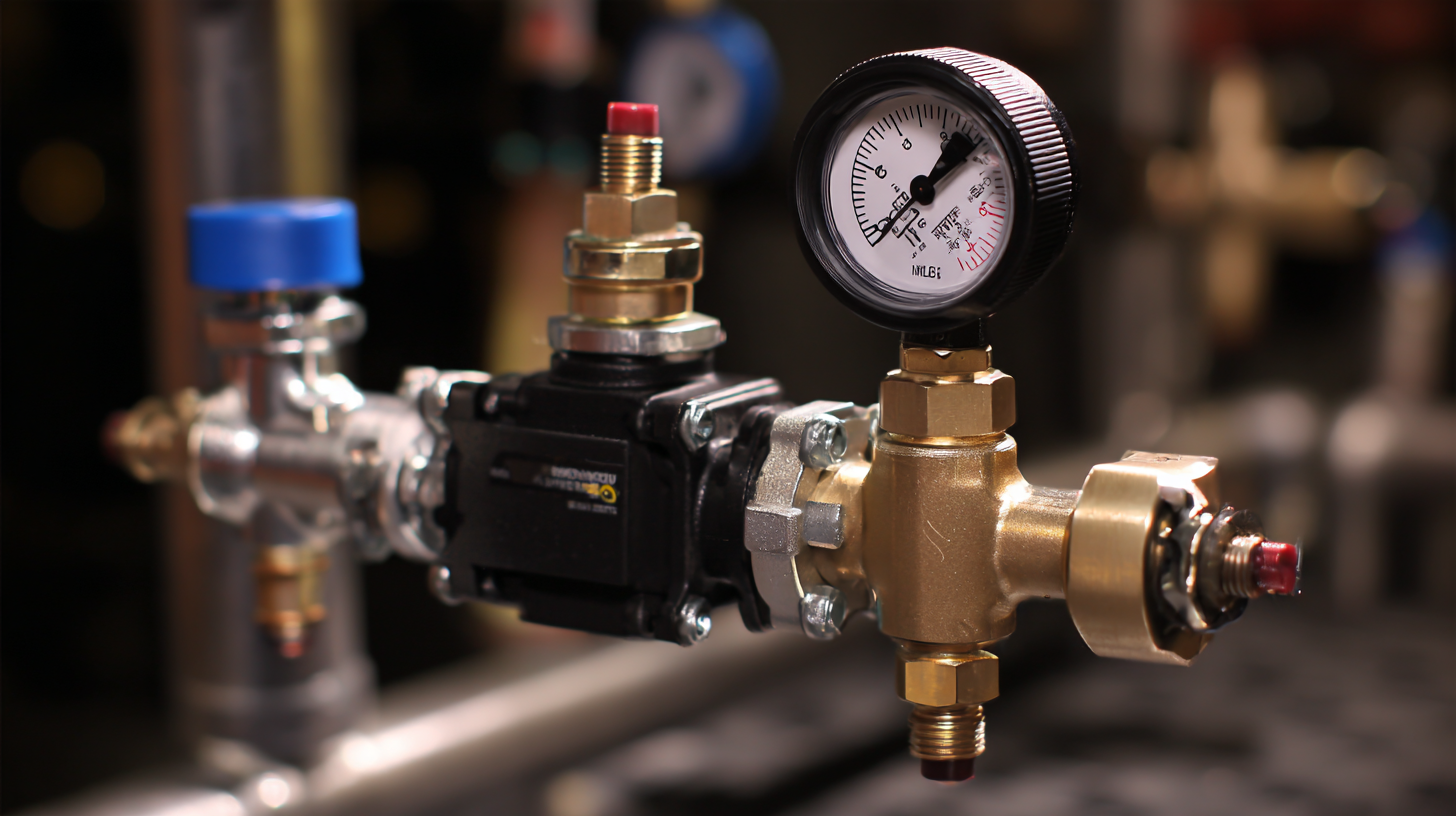

Blanket gas regulators play a critical role in various industries, ensuring the efficient management of gas flow for different applications. These regulators come in several types, each designed to cater to specific needs. For instance, pressure-reducing regulators are ideal for maintaining a constant outlet pressure, while flow control regulators are best suited for applications that require precise gas flow rates. Understanding the distinctions between these types empowers users to select the most appropriate regulator for their operations.

The application of blanket gas regulators extends beyond simple pressure control; they are essential in processes such as chemical production, food packaging, and pharmaceutical manufacturing. In the chemical industry, for example, these regulators help maintain stable conditions required for reactions, ensuring safety and efficiency. Meanwhile, in food packaging, they prevent the oxidation of products by displacing atmospheric air with inert gases. By recognizing the various types and their specific applications, users can optimize their operations and enhance overall safety.

This chart displays the efficiency percentage of different types of blanket gas regulators, showing how each type performs under standard conditions. The Low Pressure Regulator exhibits the highest efficiency, followed by the Medium Pressure Regulator, while the High Pressure Regulator shows a slightly lower efficiency.

When selecting the appropriate blanket gas regulator, it's crucial to consider several key factors to ensure optimal performance and safety. First and foremost, you should assess the type of gas you are using, as different gases require specific regulators designed to handle their properties. Additionally, consider the pressure range needed for your application. Many regulators are available with adjustable settings, which can provide flexibility depending on your process requirements.

**Tips:** Always check the manufacturer’s specifications for compatibility with your gas type to prevent any safety hazards. Moreover, you should evaluate the flow rate capacity; a regulator that cannot handle the required flow can lead to inefficiencies and potential operational issues.

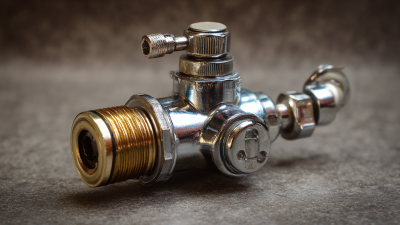

Another vital aspect is the regulatory environment in your region. Ensure that the regulator meets applicable safety and quality standards dictated by local regulations. Consider investing in a regulator that offers features like built-in pressure gauges or safety relief valves, which can enhance operational safety.

**Tips:** Look for models with user-friendly interfaces for easier adjustments and monitoring, especially in complex setups. Investing time in the selection process will pay off in reliability and safety for your operations.

| Feature | Importance | Recommended Value | Notes |

|---|---|---|---|

| Pressure Regulation | Critical for safe operation | 0-100 psi | Choose based on application specifications |

| Flow Rate | Affects process efficiency | 10-50 SCFM | Consider peak usage |

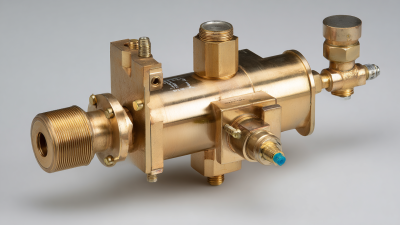

| Material Compatibility | Prevents corrosion | Brass, stainless steel | Match with blanket gas type |

| Temperature Range | Ensures functionality | -20°C to 60°C | Check environmental conditions |

| Regulator Type | Affects installation and maintenance | Single-stage, double-stage | Consider pressure fluctuations |

When selecting a blanket gas regulator, understanding industry standards is crucial for ensuring compliance in gas regulation systems. These standards are set by organizations such as the American Society of Mechanical Engineers (ASME) and the National Fire Protection Association (NFPA). Compliance with these guidelines not only guarantees safety but also enhances the efficiency of gas operations. Regulators must meet specific performance metrics, including pressure and flow rates, to be deemed suitable for use in various applications.

Furthermore, the design and construction of gas regulators are subject to rigorous testing and certification processes. This includes verifying materials used and ensuring they can withstand high pressures without failure. Regular inspections and maintenance in accordance with these standards are also essential to prevent any malfunctions that could lead to hazardous situations. By prioritizing compliance, businesses can minimize risks and ensure that their blanket gas regulators operate within the safe parameters required by law, thereby protecting both personnel and infrastructure from potential gas-related incidents.

When selecting the appropriate blanket gas regulator, performance metrics such as flow rates and pressure stability are paramount. Flow rates indicate the volume of gas that can be delivered over time, significantly affecting process efficiency and the overall performance of the system. It's essential to choose a regulator capable of handling maximum flow requirements without risking pressure drops or fluctuations, which could compromise safety and operational integrity.

Pressure stability is another critical factor in the performance of a blanket gas regulator. Consistent pressure ensures that processes remain predictable, minimizing the risk of surges or drops that could lead to product inconsistency or equipment failure. Regulators equipped with advanced pressure control technologies effectively dampen variations, offering a reliable solution for achieving optimal performance in various applications. Ensuring that both flow rates and pressure stability meet the specific needs of the operation will ultimately contribute to a more efficient and safe working environment.

When selecting a blanket gas regulator, cost-effectiveness and longevity should be at the forefront of your decision-making process. A high-quality regulator can substantially reduce operational costs over time by minimizing gas wastage and ensuring efficient performance. Investing in a durable model made from robust materials will not only decrease the frequency of repairs and replacements but also enhance overall safety in your facility.

Moreover, evaluating long-term savings requires an understanding of the regulator's life cycle. Cheaper options may seem appealing initially, but they often yield higher maintenance costs and shorter lifespans. By comparing features such as pressure stability, flow rates, and compliance with industry standards, you can identify regulators that offer both reliability and value.

Ultimately, a thoughtful investment in an effective blanket gas regulator will lead to improved productivity, safety, and profitability in the long run.