Leave Your Message

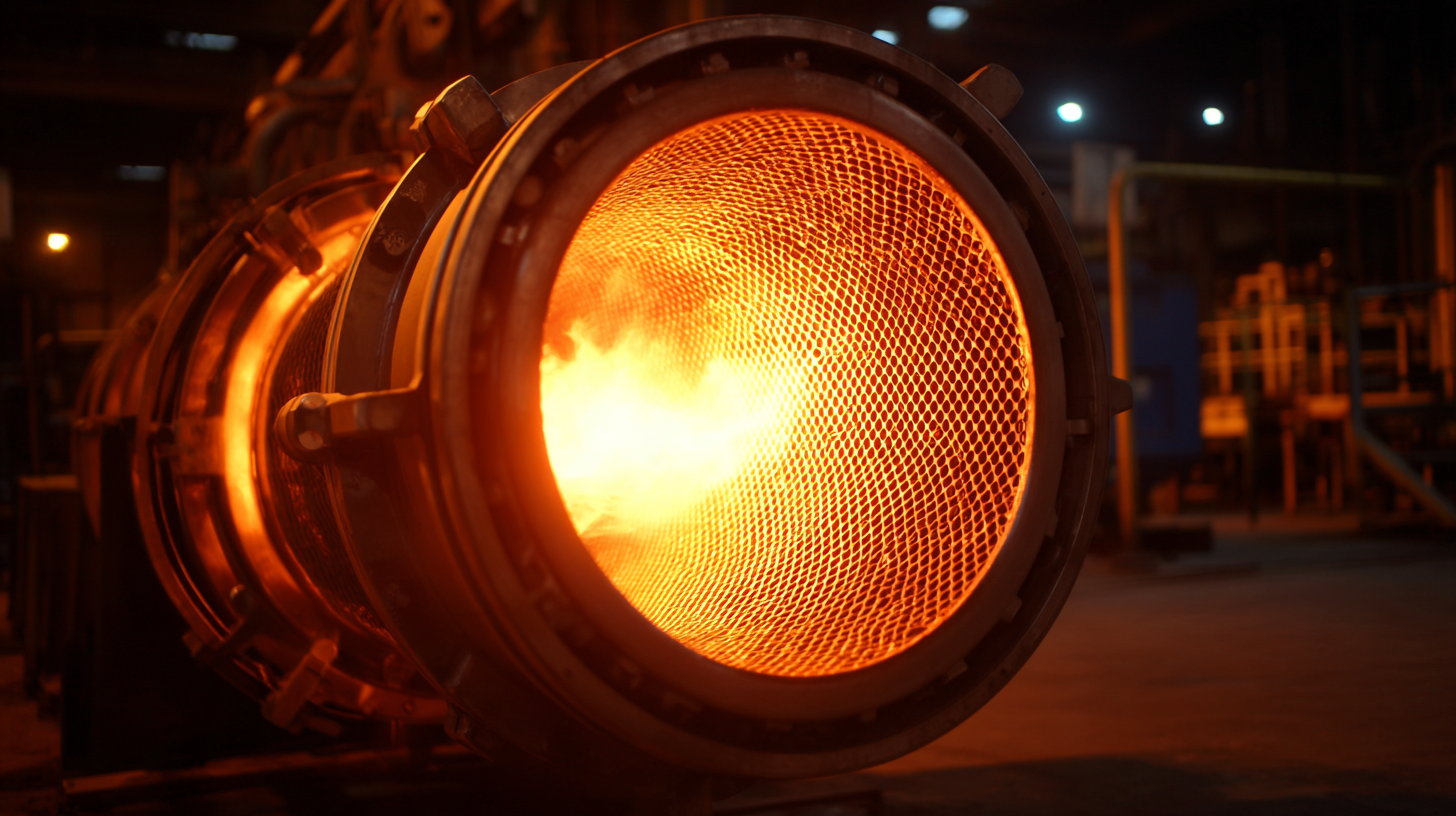

In the realm of industrial safety and fire prevention, the Inline Flame Arrestor serves as a critical component in mitigating the risks associated with flammable gases and vapors. These devices are engineered to effectively manage potential flame propagation within pipelines, ensuring that any combustion event is contained and does not compromise the safety of the surrounding environment. With increasing regulatory demands and the need for enhanced safety measures in industrial operations, understanding the function, implementation, and benefits of Inline Flame Arrestors has never been more vital. This article delves into the essential role that these innovative devices play in safeguarding facilities, protecting personnel, and maintaining operational integrity. By exploring their design, application, and best practices, we aim to highlight why Inline Flame Arrestors are indispensable in the arsenal of fire prevention strategies within various industries.

Inline flame arrestors play a crucial role in ensuring safety across various industrial applications, particularly in environments where flammable gases and vapors are present. These devices are designed to prevent the propagation of flames through piping systems, thereby protecting both personnel and infrastructure. A well-designed flame arrestor combines several key features: a reliable thermal barrier, a robust material able to withstand extreme conditions, and a configuration that allows for unobstructed flow, all while effectively extinguishing flames. According to industry reports, the global flame arrestor market is projected to grow significantly, driven by increased safety regulations in industrial sectors.

Moreover, inline flame arrestors serve vital functions beyond mere fire prevention. They enhance operational efficiency by ensuring that equipment remains functional in hazardous conditions, thereby reducing the risk of costly downtimes and repairs. The use of flame arrestors can significantly decrease the potential for catastrophic incidents, with studies indicating that proper installation can reduce fire-related accidents by over 30%. As industries continue to evolve, the integration of advanced safety mechanisms, including inline flame arrestors, remains essential to fostering a safer working environment.

Inline flame arrestors play a crucial role in enhancing industrial safety and fire prevention. Their primary function is to prevent the propagation of flames through pipelines, which is vital in environments where flammable gases and liquids are handled. The integration of these devices can significantly reduce the risk of catastrophic accidents, particularly in industrial settings that have recently witnessed devastating fires, as reported in various incidents. Such events highlight the urgent need for effective fire prevention measures, reaffirming the importance of inline flame arrestors.

The top benefits of using inline flame arrestors include the enhancement of operational safety, compliance with regulatory standards, minimization of fire risks, protection of equipment, and the potential for cost savings. By preventing flames from traveling back into the system, these devices safeguard critical infrastructure and ensure that processes remain uninterrupted. Furthermore, as industries increasingly turn to innovative approaches to fire safety, the implementation of inline flame arrestors stands out as a proactive step toward safeguarding both personnel and assets against the ever-looming threat of fire.

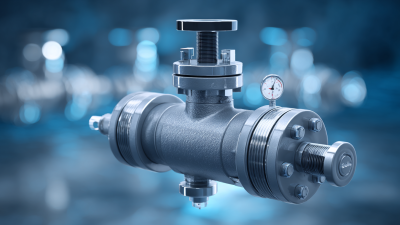

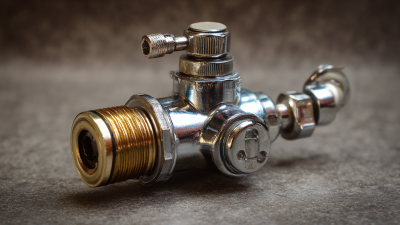

Inline flame arrestors are crucial components in industrial settings, designed to prevent flames from propagating through pipelines carrying flammable gases or vapors. These devices operate on a fundamental principle of thermal inertia, which involves dissipating heat from a flame before it can travel upstream through the system. The arrestor contains a series of baffles or mesh materials that create turbulence, effectively cooling the flame front as it encounters these obstacles. By reducing the temperature and extinguishing potential flames, inline flame arrestors help to safeguard equipment and personnel from fire hazards.

Inline flame arrestors are crucial components in industrial settings, designed to prevent flames from propagating through pipelines carrying flammable gases or vapors. These devices operate on a fundamental principle of thermal inertia, which involves dissipating heat from a flame before it can travel upstream through the system. The arrestor contains a series of baffles or mesh materials that create turbulence, effectively cooling the flame front as it encounters these obstacles. By reducing the temperature and extinguishing potential flames, inline flame arrestors help to safeguard equipment and personnel from fire hazards.

The effectiveness of inline flame arrestors lies in their ability to interrupt flame propagation, thereby containing potential explosions within the pipe system. When a flame activates, the temperature rises rapidly, and the arrestor's design allows it to absorb and dissipate that heat. Additionally, the flow resistance created by the internal structure of the device further inhibits the flame's movement, ensuring that any ignition source is promptly neutralized. This mechanism not only enhances the safety of industrial operations but also contributes to the overall integrity of the process, making inline flame arrestors an indispensable element in fire prevention strategies.

Maintaining inline flame arrestors is crucial for ensuring optimal performance and safety in industrial operations. Regular inspection is essential, as these devices serve as a barrier to prevent flames from propagating through piping systems. Operators should check for carbon buildup and any signs of corrosion that might compromise the integrity of the arrestor. Implementing a routine maintenance schedule can help identify potential issues before they escalate, providing an added layer of security.

Cleaning flame arrestors is another critical maintenance task. Accumulated debris can obstruct the flow of gases and reduce the effectiveness of the arrestor. Utilizing a soft brush and a suitable solvent can help remove any residue without damaging sensitive components. Additionally, replacement of worn parts must be done promptly, as compromised arrestors can lead to catastrophic incidents. Adhering to the manufacturer’s guidelines regarding maintenance and replacement intervals ensures that inline flame arrestors operate effectively, thereby safeguarding the facility and its personnel.

Inline flame arrestors are crucial components in many industrial systems, yet numerous misconceptions surrounding their function persist. One common myth is that inline flame arrestors are a guarantee against explosions and fires. While these devices significantly reduce the likelihood of flame propagation through pipelines, they do not eliminate the inherent risks associated with flammable gases and vapors. According to a report by the National Fire Protection Association (NFPA), nearly 40% of industrial fires arise from improper handling and storage of flammable materials, underscoring the need for comprehensive safety protocols in conjunction with flame arrestors.

Another prevalent misconception is that all flame arrestors are created equal. In reality, the effectiveness of these devices varies based on design and application. For instance, a study by the American Institute of Chemical Engineers (AIChE) highlights that flame arrestors must be selected based on specific operational parameters, such as pressure and flow conditions, to ensure optimal performance. Choosing the right type of flame arrestor can mean the difference between mitigation and catastrophe, emphasizing the importance of understanding their role in fire prevention strategies within various industrial contexts.