Leave Your Message

In the field of industrial pressure management, the efficiency of Nitrogen Pressure Relief Valves (NPRVs) is paramount for ensuring safety and operational effectiveness. According to a report by the International Society of Automation, improper functioning of relief valves can lead to significant risks, with nearly 30% of industrial accidents attributed to valve failures (ISA, 2021). Furthermore, advancements in technology are paving the way for innovative solutions that optimize the performance of NPRVs, enhancing their reliability and responsiveness. Implementing smart monitoring systems and data analytics can reduce maintenance costs by up to 25%, as highlighted in a recent industry study by the American Society of Mechanical Engineers (ASME, 2022). This article provides insights and practical tips aimed at improving the functionality and longevity of Nitrogen Pressure Relief Valves, ensuring they meet the rigorous demands of modern industrial applications.

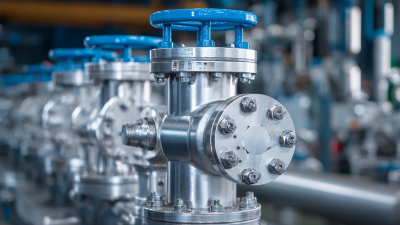

Innovative design approaches are crucial for enhancing the efficiency of nitrogen pressure relief valves, a vital component in various industrial applications. According to a recent market analysis by Research and Markets, the global demand for pressure relief valves is expected to grow at a CAGR of 4.5% from 2023 to 2030, driven by the rising need for effective pressure management in industries such as oil and gas, chemicals, and pharmaceuticals. Implementing innovative materials and design techniques not only improves durability but also optimizes operational performance under varying pressure conditions.

One significant advancement is the integration of smart technologies into valve designs. By utilizing IoT-enabled sensors, manufacturers can provide real-time monitoring and data analytics, allowing for proactive maintenance and reducing the risk of failure. A report from MarketsandMarkets highlights that the adoption of smart pressure relief valves could enhance overall system efficiency by up to 30%. Additionally, advancements in computational fluid dynamics (CFD) have led to better flow optimization within the valve, minimizing energy losses and enhancing response times. These innovative approaches not only ensure compliance with stringent safety regulations but also contribute significantly to operational cost savings across industries.

| Parameter | Value | Unit |

|---|---|---|

| Max Operating Pressure | 150 | psig |

| Set Pressure | 100 | psig |

| Safety Valve Size | 3 | inches |

| Material | Stainless Steel | N/A |

| Response Time | 0.5 | seconds |

| Operational Temperature | -20 to 150 | °C |

| Flow Coefficient (Cv) | 20 | N/A |

| Test Standard | API 527 | N/A |

In the realm of pressure relief systems, the integration of emerging technologies for predictive maintenance is revolutionizing how we ensure optimal performance of nitrogen pressure relief valves. By leveraging data analytics, machine learning, and IoT sensors, companies can now predict potential failures before they occur. This proactive approach not only extends the lifespan of the valves but also significantly reduces downtime and maintenance costs.

Tips: To maximize the effectiveness of your predictive maintenance strategy, consider investing in advanced sensor technology that provides real-time data on valve performance. Regularly analyze this data to identify trends and patterns that could indicate potential issues. Establish a routine for fine-tuning your predictive algorithms, adjusting them based on operational conditions and historical performance data.

Moreover, the application of digital twins—virtual replicas of physical systems—allows for in-depth simulation and monitoring. Engineers can model pressure relief systems to assess how they would react under various scenarios, leading to enhanced design and operational strategies.

Tips: Collaborate with technology providers who offer data integration solutions to create a comprehensive maintenance dashboard. This will facilitate streamlined communication among team members and allow for quicker decision-making when it comes to valve maintenance or replacement.

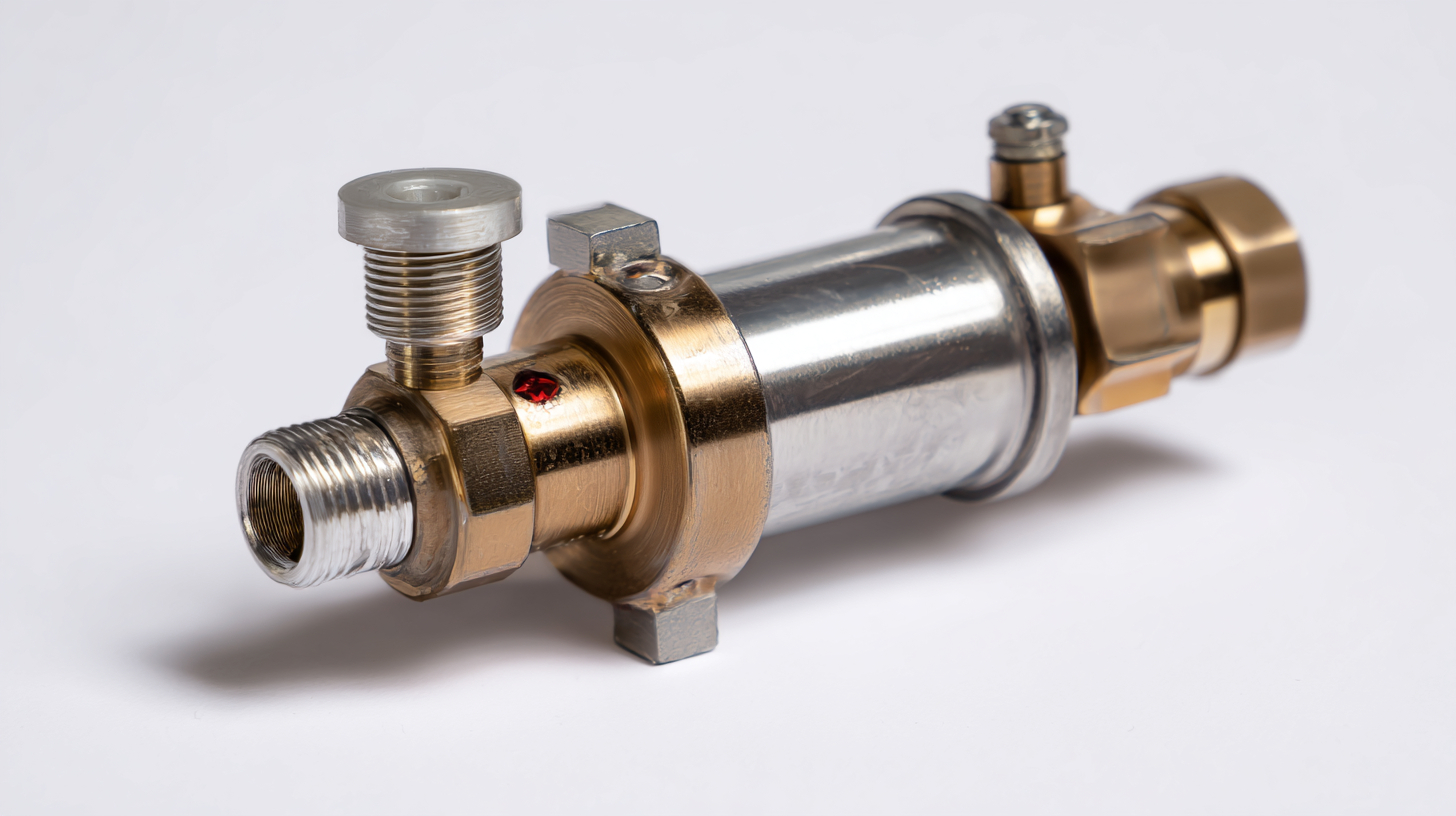

The performance of nitrogen pressure relief valves is significantly influenced by the materials from which they are constructed. Advanced materials such as high-strength alloys and composite polymers offer enhanced resistance to corrosion and wear, ensuring a longer lifespan and more reliable operation in demanding environments. These materials can withstand the harsh conditions often encountered in industrial applications, reducing the frequency of maintenance and unexpected failures.

Additionally, the properties of advanced materials contribute to improved sensitivity and responsiveness of the valves. With precise engineering and innovative design, these materials can reduce the weight of the valves while enhancing their structural integrity. This optimization allows for more efficient pressure management, with valves reacting quickly to changes in system pressure, thus maintaining optimal performance and safety. The integration of such materials into the design of nitrogen pressure relief valves exemplifies how innovation can lead to significant performance improvements in crucial safety devices.

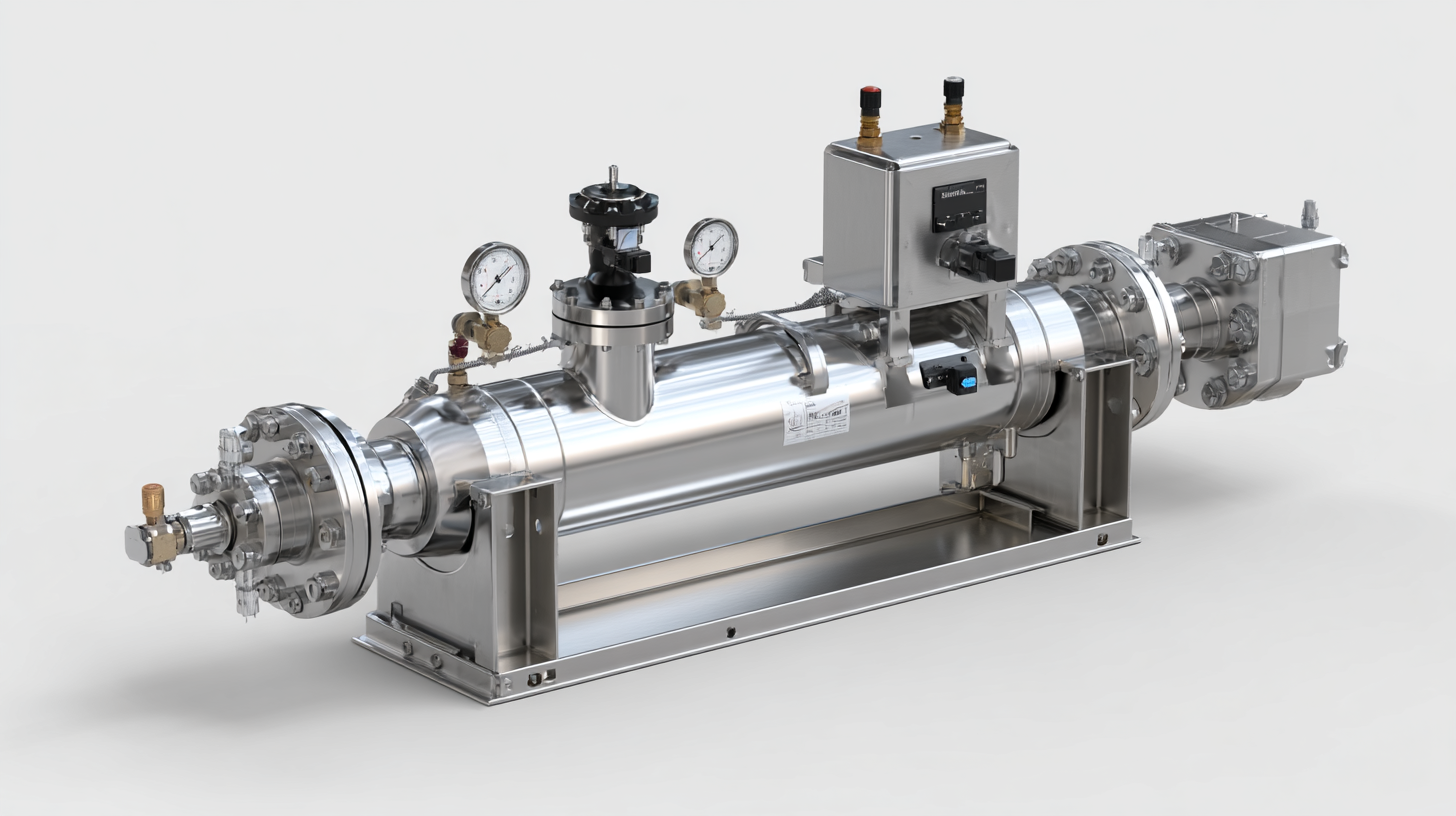

The implementation of high-performance nitrogen pressure relief valves has proven crucial in various industrial settings, particularly in the oil and gas sector. According to a report by the National Association of Corrosion Engineers (NACE), improper valve performance can lead to operational inefficiencies and significant financial losses, with estimated costs reaching up to $1 million per incident due to equipment failures and safety incidents. Case studies from leading companies have showcased how advanced engineering solutions have optimized the functionality of nitrogen pressure relief systems, resulting in enhanced safety and reduced downtime.

One notable case study involved a major petroleum refining facility that integrated smart technology into their nitrogen pressure relief valves. By leveraging real-time monitoring systems, the facility reduced valve failure rates by 40%. Furthermore, a recent study by the American Petroleum Institute (API) emphasized that companies utilizing these innovative pressure relief solutions reported a 30% decrease in emergency venting and a corresponding increase in system reliability. These examples underline the critical role of innovative design and technology in achieving optimal performance, ultimately supporting operational excellence within the industry.

This chart illustrates the performance metrics of nitrogen pressure relief valves before and after the implementation of high-performance solutions. The data focuses on pressure relief efficiency and operational reliability over a series of case studies.

In the realm of industrial safety, regulatory compliance plays a fundamental role in optimizing nitrogen pressure relief valve systems. The Occupational Safety and Health Administration (OSHA) and the American Society of Mechanical Engineers (ASME) set forth stringent guidelines to ensure that pressure relief devices, including nitrogen valves, operate efficiently under varying environmental conditions. According to the National Board of Boiler and Pressure Vessel Inspectors, improper valve sizing or failure to adhere to established standards can lead to catastrophic failures, emphasizing the necessity for stringent compliance and regular maintenance.

In the realm of industrial safety, regulatory compliance plays a fundamental role in optimizing nitrogen pressure relief valve systems. The Occupational Safety and Health Administration (OSHA) and the American Society of Mechanical Engineers (ASME) set forth stringent guidelines to ensure that pressure relief devices, including nitrogen valves, operate efficiently under varying environmental conditions. According to the National Board of Boiler and Pressure Vessel Inspectors, improper valve sizing or failure to adhere to established standards can lead to catastrophic failures, emphasizing the necessity for stringent compliance and regular maintenance.

Moreover, compliance not only helps in mitigating risks but also enhances operational performance. A recent report by the International Society of Automation (ISA) highlighted that facilities adhering to regulatory standards achieved up to 30% greater efficiency in their relief systems compared to non-compliant facilities. The integration of advanced monitoring technologies can further facilitate compliance, allowing for real-time analysis and adjustments to relieve valve performance, thereby ensuring safety and reliability. Implementing these solutions not only meets regulatory requirements but also fosters a culture of safety and operational excellence within organizations.