Leave Your Message

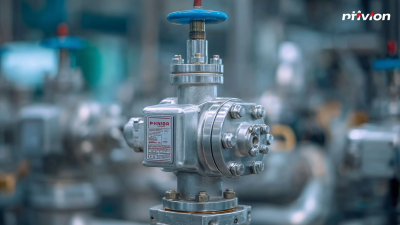

In an increasingly automated industrial landscape, the importance of safety and efficiency cannot be overstated. Vacuum Relief Valves play a crucial role in safeguarding systems against negative pressure fluctuations, which can lead to equipment failure and costly downtime.

According to a report by Allied Market Research, the global market for industrial valves, including vacuum relief valves, is expected to reach $97.5 billion by 2027, growing at a CAGR of 5.2%. As industries strive for enhanced operational reliability amidst stringent regulatory requirements, understanding the functionality and application of Vacuum Relief Valves becomes essential for beginners and seasoned professionals alike.

This comprehensive guide aims to bridge that knowledge gap, providing insights into selecting, installing, and maintaining these vital components to ensure optimal performance and safety.

Vacuum relief valves play a critical role in maintaining the integrity and safety of vacuum systems by preventing the formation of harmful sub-atmospheric pressures. These valves are designed to open when the pressure inside a vessel falls below a predetermined level, allowing air to enter and preventing collapse. Understanding the functionality of vacuum relief valves is essential for any beginner in the field, especially given their importance in various applications, from industrial processing to transportation of cryogenic liquids.

Vacuum relief valves play a critical role in maintaining the integrity and safety of vacuum systems by preventing the formation of harmful sub-atmospheric pressures. These valves are designed to open when the pressure inside a vessel falls below a predetermined level, allowing air to enter and preventing collapse. Understanding the functionality of vacuum relief valves is essential for any beginner in the field, especially given their importance in various applications, from industrial processing to transportation of cryogenic liquids.

In recent industry developments, some manufacturers have emphasized the need for reliable and efficient vacuum relief solutions. For instance, reports indicate that safety vacuum release systems (SVRS) have gained traction for their ability to respond swiftly to pressure changes, ensuring system stability. These systems significantly reduce the risk of vessel implosion, especially in scenarios involving high vacuum environments. Furthermore, advancements in valve technology, such as high vacuum gate valves, showcase innovative designs intended for rugged conditions and enhanced performance in critical applications.

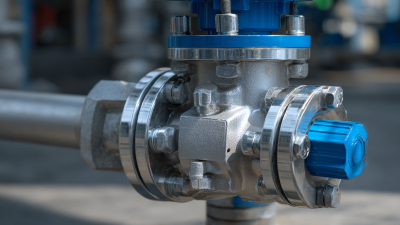

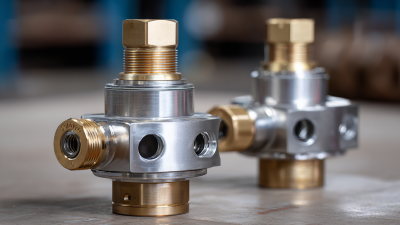

Besides safety, the choice of materials in vacuum valve construction is vital. For instance, valves crafted from specially treated stainless steel ensure durability even in harsh environments, such as offshore applications or those involving corrosive substances. As the industry evolves, the incorporation of advanced materials and technologies into vacuum relief valves continues to enhance their functionality and reliability, making them indispensable in modern engineering and processing systems.

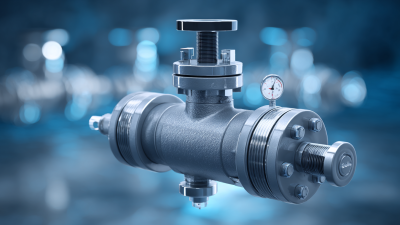

Vacuum relief valves (VRVs) are critical components in various industries, designed to maintain pressure levels within vessels and prevent collapse under negative pressure conditions. Understanding the essential components of VRVs is vital for anyone looking to master their functionality. Key parts typically include the valve body, spring mechanism, and sealing elements. The valve body houses the internal components and is constructed from materials like stainless steel or PVC, depending on the application and fluid characteristics. According to a report by Frost & Sullivan, the global market for vacuum relief valves is projected to grow at a compound annual growth rate (CAGR) of 4.5% through 2025, underscoring their importance in maintaining system integrity.

Another critical component to note is the spring mechanism, which determines the valve's opening pressure. Typically, the spring is designed to hold the valve closed until a specified negative pressure is reached, at which point it opens to allow air ingress. A study by MarketsandMarkets highlights that improper functioning of vacuum relief valves can lead to significant operational hazards, including equipment failure and increased downtime, emphasizing that proper selection and maintenance of these valves are paramount for operational safety and efficiency. Additionally, sealing elements play a crucial role in ensuring that the valve functions correctly, preventing leaks when the valve is closed and maintaining optimal pressure conditions. Understanding these components helps in selecting the right valve for specific applications, enhancing both safety and productivity.

| Component | Function | Material | Working Pressure (psi) | Temperature Range (°F) |

|---|---|---|---|---|

| Body | Contains and directs fluid | Forged Steel | 150 | -20 to 250 |

| Diaphragm | Controls the opening and closing | EPDM | 100 | -20 to 180 |

| Spring | Provides necessary force for operation | Stainless Steel | 120 | -40 to 250 |

| Vent Port | Allows air influx to prevent vacuum | Plastic/Metal | Varies | -20 to 300 |

| Seal | Prevents leaks around joints | Nitrile | 90 | -30 to 200 |

When selecting the right vacuum relief valve, a systematic approach can help ensure that you make an informed choice. First, it’s crucial to understand the specific application and operating conditions of your system. Factors such as the type of fluid being handled, temperature ranges, and potential pressures should all influence your selection. Additionally, consider whether your system will be subject to varying vacuum levels or if a constant setting is required.

Next, evaluate the materials used in the valve's construction. This is essential for ensuring durability and compatibility with the media being processed. For instance, stainless steel valves may be preferable in corrosive environments, while plastic options could suffice for less demanding applications. Furthermore, ensure the valve has the appropriate size and flow rate to avoid restrictions that could lead to performance issues.

Finally, always check for compliance with industry standards and regulations relevant to your application. This ensures not only the safety and reliability of the valve but also that it meets the quality requirements for your specific sector. By following this checklist, you'll be well on your way to selecting a vacuum relief valve that meets your needs effectively.

Vacuum relief valves play a crucial role in maintaining the integrity and performance of vacuum systems. Regular maintenance is key to ensuring these valves operate effectively. Start by conducting routine inspections for signs of wear or corrosion. Over time, components can wear down, leading to potential leaks or malfunction. It is advisable to clean the valve periodically to prevent dirt and debris from causing blockages. Utilizing proper cleaning techniques can significantly enhance the longevity of the valve and preserve its functionality.

Vacuum relief valves play a crucial role in maintaining the integrity and performance of vacuum systems. Regular maintenance is key to ensuring these valves operate effectively. Start by conducting routine inspections for signs of wear or corrosion. Over time, components can wear down, leading to potential leaks or malfunction. It is advisable to clean the valve periodically to prevent dirt and debris from causing blockages. Utilizing proper cleaning techniques can significantly enhance the longevity of the valve and preserve its functionality.

Another essential aspect of maintaining vacuum relief valves is checking the sealing mechanisms. Seals that are cracked or deteriorated can lead to vacuum leaks, reducing system efficiency. Replacing seals as part of a regular maintenance schedule will help mitigate this risk. Additionally, familiarize yourself with the specific requirements of your vacuum system, as different types may have unique maintenance needs. By prioritizing these maintenance tips, you can ensure optimal performance and reliability from your vacuum relief valves, much like how maintaining other components, such as fuel injectors or optical sorters, contributes to overall system efficiency.

When dealing with vacuum relief valves, understanding common troubleshooting steps can significantly enhance their efficiency and longevity. Many users face issues such as inadequate vacuum pressure or leaks, which can compromise system performance. One of the first steps in troubleshooting is to inspect the valve for any visible signs of damage or wear. This includes checking the seals and seating surfaces, as any imperfections here can lead to failure in maintaining the correct vacuum levels. In many cases, simply cleaning or replacing these components can resolve the issue.

Another vital troubleshooting step is to verify that the valve is functioning correctly under operational conditions. This involves testing the valve's response to pressure changes within the system. If the valve fails to open or close at the specified pressures, it may require recalibration or replacement. Additionally, ensure that there are no blockages in the system leading to the valve, as these can disrupt its operation and lead to erratic performance. Regular maintenance, including periodic inspections and calibrations, can prevent many common issues and ensure that your vacuum relief valve operates effectively in any system.