Leave Your Message

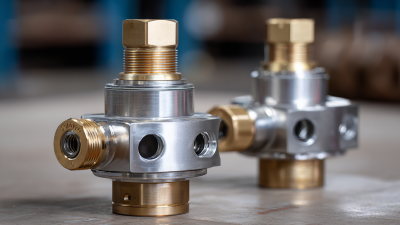

In today's competitive industrial landscape, optimizing processes is crucial for enhancing efficiency and reducing operational costs. One effective solution gaining traction is the implementation of Vacuum Sequence Valves (VSVs). According to a recent report by the International Society for Automation, industries utilizing advanced valve technologies have reported efficiency improvements of up to 25% in key applications. VSVs play a pivotal role by ensuring controlled sequences of vacuum operations, which minimizes energy waste and maximizes throughput. As companies strive to meet rising production demands while adhering to stringent efficiency standards, the strategic integration of Vacuum Sequence Valves is not just beneficial but essential. By understanding their functionality and potential impact, businesses can position themselves for sustainable growth and increased competitiveness in the market.

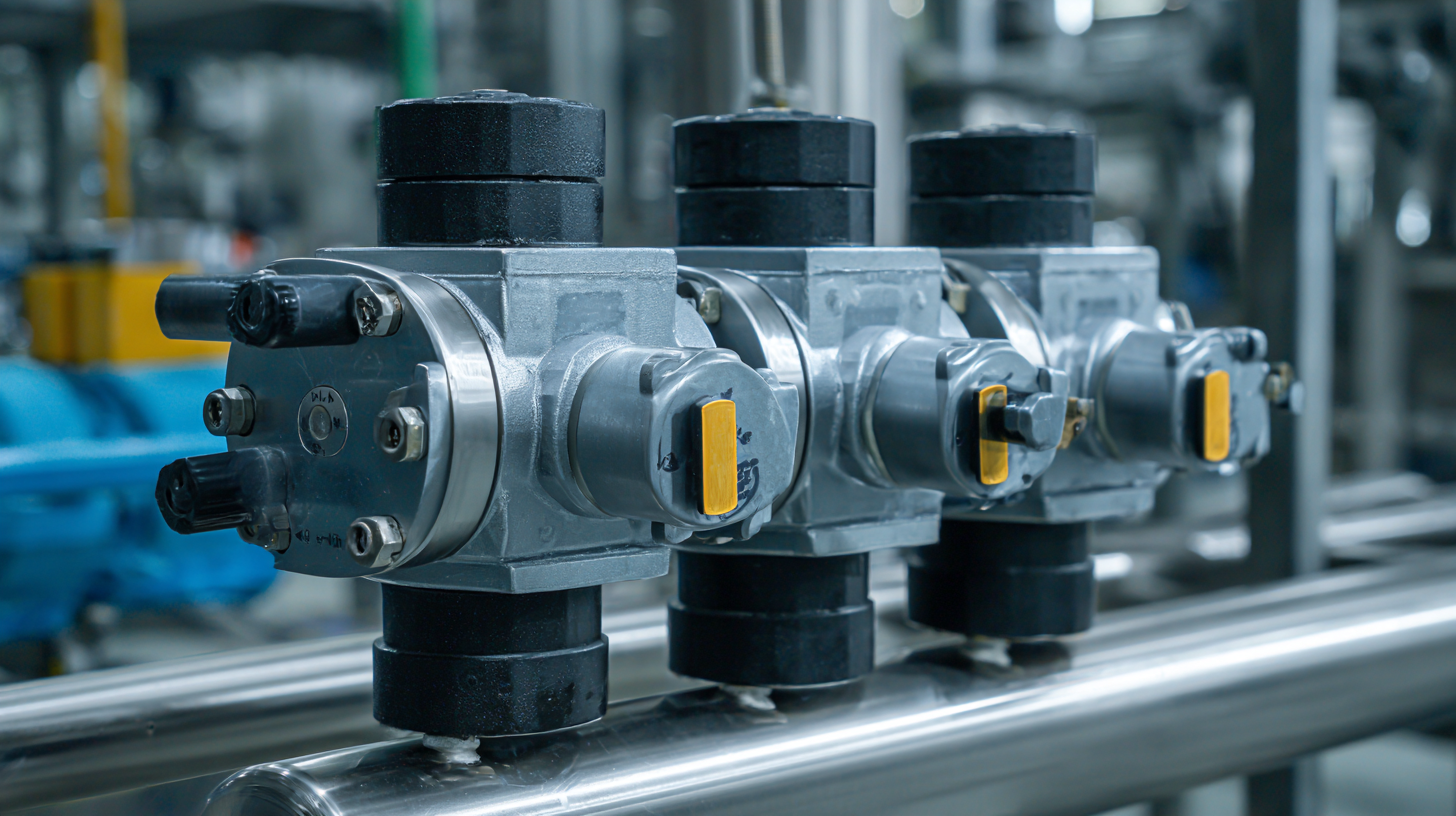

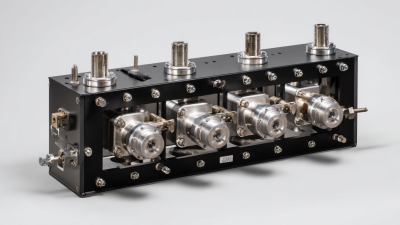

Vacuum sequence valves play a pivotal role in enhancing the operational efficiency of industrial systems. By coordinating the sequence of vacuum application and release, these valves can ensure that materials are processed without interruptions. This is especially critical in environments where the precision of material handling is essential, such as in the packaging or pharmaceutical industries. Understanding how these valves function involves recognizing their ability to manage multiple inputs and outputs, much like the fluidic soft robots that utilize multiple lines for precise control. This synergy allows for improved task coordination and optimized performance.

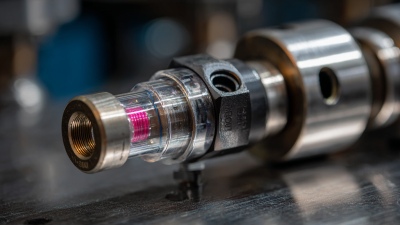

**Tip 1:** Regular maintenance of vacuum sequence valves is vital to ensure their efficient operation. Check for leaks and wear, as these can significantly impact performance.

As industries evolve towards more automated processes, integrating advanced components like vacuum sequence valves will become increasingly important. Their functionality in regulating airflow can help industrial systems perform smoother and achieve higher levels of automation. The advancements seen in fluidic soft robots suggest that similar principles can apply, enhancing flexibility and responsiveness in various applications.

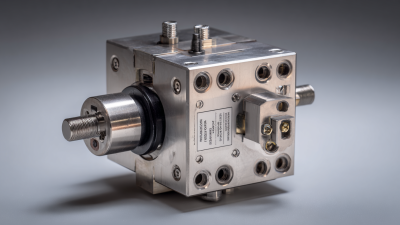

**Tip 2:** When selecting a vacuum sequence valve, consider the specific requirements of your application, such as pressure ranges and materials, to ensure optimal integration with existing systems.

This chart illustrates the efficiency improvements achieved before and after the implementation of vacuum sequence valves in industrial processes. The data indicates a significant increase in efficiency from 60% to 85%. Implementing these valves can enhance operational performance in various industrial applications.

Implementing vacuum sequence valves in industrial processes can significantly enhance operational efficiency. These valves streamline the control of fluid dynamics by allowing for more precise management of pressure and flow, minimizing energy loss and operational downtime. By optimizing the sequence of valve operations, industries can effectively reduce the costs associated with energy consumption, ultimately contributing to a more sustainable production model.

The benefits of utilizing vacuum sequence valves extend beyond just energy savings. These valves can improve the overall reliability of production systems by ensuring consistent performance under varying operational conditions. Furthermore, the integration of such advanced technologies can facilitate better data collection and analysis, akin to advancements in high-throughput single-cell RNA sequencing techniques. This constant feedback loop enhances the understanding of process variables, allowing for smarter decision-making and more rapid adaptations to production challenges. By adopting vacuum sequence valves, industries can position themselves at the forefront of efficiency and innovation.

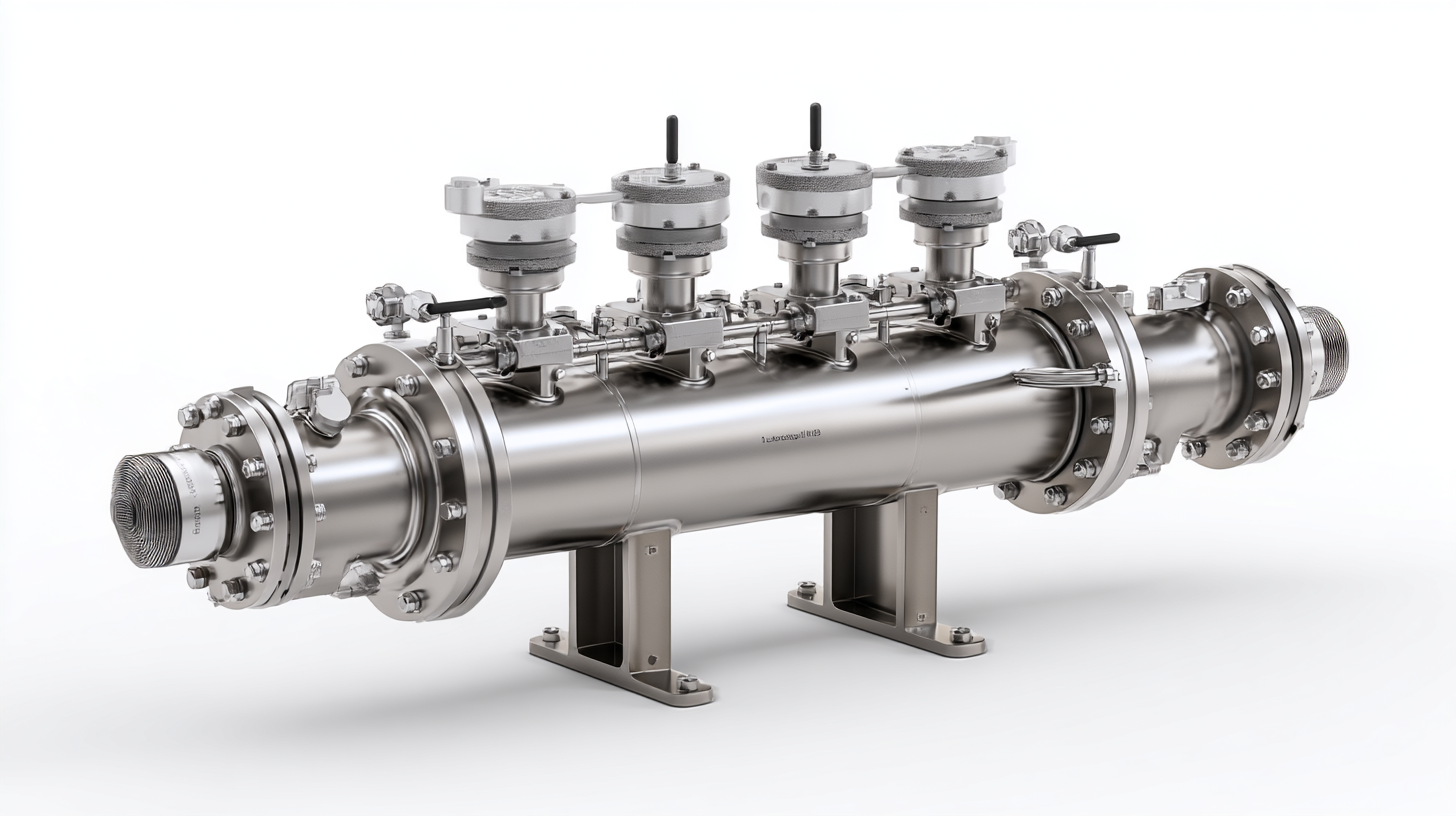

Integrating vacuum sequence valves into existing industrial processes can significantly enhance operational efficiency. According to a report by the European Vacuum Industry Association, processes utilizing vacuum technology have reported efficiency improvements of up to 30%. The first step in this integration involves conducting a thorough assessment of current systems to identify areas where vacuum sequence valves can be most beneficial. This includes evaluating the existing flow patterns, pressure conditions, and the specific demands of the application.

Once the assessment is complete, it’s crucial to select the appropriate vacuum sequence valves that align with the operational requirements. Data from the International Society for Automation indicates that proper valve selection can lead to a reduction in energy consumption by as much as 25%. Installation should then be carried out according to manufacturer specifications, ensuring that all components are compatible and optimize the overall system performance. Regular monitoring and maintenance following the installation stage will further support enhanced efficiency, allowing for real-time adjustments and operational insights.

| Process Step | Current Efficiency (%) | Optimized Efficiency (%) | Expected Savings ($) | Implementation Time (Weeks) |

|---|---|---|---|---|

| Initial Setup | 75 | 85 | 2000 | 4 |

| Testing Phase | 80 | 90 | 1500 | 3 |

| Integration with Existing Systems | 70 | 80 | 2500 | 5 |

| Full Operation | 85 | 95 | 3000 | 2 |

| Monitoring and Adjustment | 78 | 88 | 1800 | 3 |

The implementation of vacuum sequence valves in industrial processes can significantly enhance operational efficiency; however, several common challenges can impede their optimization. One primary issue is ensuring compatibility with existing systems. According to a recent report by the International Society of Automation, up to 30% of industrial failures can be attributed to improper integration of new technologies with legacy systems. This highlights the importance of conducting thorough compatibility assessments before integrating vacuum sequence valves into existing processes.

Another challenge faced in optimizing industrial processes with vacuum sequence valves is the need for regular maintenance and monitoring. A survey by the European Federation of Automation and Control (EFAC) revealed that facilities that implement preventative maintenance schedules can increase their uptime by over 25%. However, many organizations still rely on reactive maintenance practices, which can lead to unplanned downtimes and increased operational costs. To address this, companies must invest in training their personnel and adopting predictive maintenance technologies that can better anticipate potential failures in vacuum systems, thereby enhancing overall process efficiency and productivity.

Monitoring and maintaining vacuum sequence valves is critical for ensuring long-term performance and efficiency in industrial processes. According to a report by the International Vacuum Association, regular maintenance can enhance the operational lifetime of vacuum systems by up to 30%. This underscores the importance of establishing a routine maintenance schedule to inspect valve seals, actuators, and control systems. A study from the American Society of Mechanical Engineers indicates that neglecting routine checks can lead to a dramatic decline in system efficiency, often resulting in energy losses exceeding 20%.

In addition, employing advanced monitoring technologies can greatly improve the maintenance of vacuum sequence valves. Utilizing IoT sensors for real-time data collection allows for proactive management of valve performance, helping to identify issues before they escalate into costly downtime. A recent analysis by the Society of Manufacturing Engineers revealed that companies integrating smart monitoring solutions observed a 15% reduction in operational costs related to vacuum systems. By prioritizing the monitoring and maintenance of vacuum sequence valves, industries can not only safeguard their investments but also boost overall efficiency.