Leave Your Message

In modern industrial applications, the performance of the Vacuum Sequence Valve plays a pivotal role in ensuring operational efficiency and reliability. According to a report by Research and Markets, the global market for vacuum technology is projected to grow by approximately 7% annually, driven by the increasing demand for advanced manufacturing processes and clean energy solutions. An optimized Vacuum Sequence Valve not only maximizes the efficiency of vacuum systems but also contributes significantly to energy savings and reduced operational costs. As industries strive for enhanced productivity and sustainability, understanding the crucial benefits of optimizing these valves becomes essential. This blog will explore key strategies for enhancing the performance of your Vacuum Sequence Valve, leading to improved system efficiency and a positive impact on the overall manufacturing process.

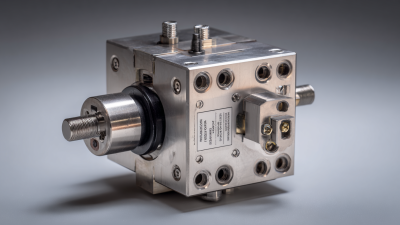

Vacuum sequence valves play a crucial role in optimizing the performance of vacuum systems by ensuring the proper sequence of valve operations. Understanding the fundamental workings of these valves is essential for achieving maximum efficiency in processes such as packaging, semiconductor manufacturing, and pharmaceutical applications. According to a 2022 report by the International Society for Vacuum Technology, effective use of vacuum sequence valves can increase system efficiency by up to 30%, significantly enhancing production rates and reducing operational costs.

The operation of a vacuum sequence valve involves a series of valves that control the flow of gases and maintain a defined pressure. In practice, a well-calibrated sequence can prevent cavitation and minimize energy consumption. A study conducted by the Vacuum Application Group demonstrated that systems employing optimized sequence valves exhibit lower pump cycling and reduced thermal loading, which contribute to longer equipment lifespan and lower maintenance costs. Maximizing the efficiency of these valves thus not only boosts operational throughput but also enhances overall sustainability in industrial applications.

When it comes to maximizing the efficiency of vacuum sequence valves, understanding the key factors that influence their performance is essential. One significant factor is the valve sizing; ensuring that the valve is appropriately sized for the application can prevent unnecessary pressure drops and enhance overall efficiency. Additionally, material selection plays a critical role. Using high-quality, durable materials can withstand the harsh conditions typically found in vacuum systems, ultimately improving the valve's longevity and performance.

Tips for optimizing your vacuum sequence valve include regular maintenance checks. Inspecting seals and gaskets for wear and tear can prevent leaks that would otherwise compromise efficiency. Implementing proper installation techniques is another crucial aspect. Ensuring that the valves are correctly aligned and securely fastened helps maintain optimal function. Lastly, consider the control systems in place: utilizing advanced automation can lead to quicker response times and finer control over the flow, significantly boosting the overall efficiency of the system.

Proper maintenance of your vacuum sequence valve is crucial to ensure optimal performance and efficiency. One of the primary tips is to regularly check and clean the valve components. Dust and debris can accumulate, leading to malfunctions. A simple cleaning with appropriate solvents can significantly enhance the valve's operation, preventing clogs that could hinder performance.

Another key maintenance tip is to regularly inspect the seals and gaskets. These components wear out over time and can lead to vacuum leaks, resulting in inefficiencies. Prompt replacement of damaged seals not only helps maintain vacuum integrity but also improves the overall lifespan of the valve system. Additionally, lubrication of moving parts should not be overlooked; using the right lubricants can reduce friction and wear, ensuring smooth operation and extending the life of the valve.

Lastly, it is essential to monitor the vacuum pressure levels frequently. Consistently tracking performance metrics allows for the early detection of irregularities that could signal potential issues. Regularly scheduled maintenance checks will proactively address these problems, keeping your vacuum sequence valve operating at peak efficiency and reliability. Adopting these simple practices can lead to a considerable enhancement in the functionality of your vacuum system.

Vacuum sequence valves play a crucial role in optimizing system performance, but issues can occasionally arise that hinder their efficiency. Common problems include leaks, improper calibration, and internal blockages. For instance, a significant vacuum leak can lead to reduced system pressure, which not only impacts the immediate performance but can also cause cascading failures in associated components. It's essential to regularly conduct diagnostics to identify these leaks early, especially in systems utilizing complex air management technologies.

**Tip:** To troubleshoot effectively, start by conducting a visual inspection for obvious signs of wear or leaks in hoses and fittings. Utilize vacuum gauges to pinpoint inconsistencies in pressure levels.

Moreover, ensure that your vacuum sequence valve is correctly calibrated to match the specific requirements of your system. With advancements in engineering and increased focus on fuel efficiency, modern vehicles often feature sophisticated air intake and boost management systems that depend heavily on the efficient operation of these valves.

**Tip:** Refer to manufacturer specifications for calibration procedures and consider using advanced diagnostic tools to fine-tune performance parameters, enhancing both responsiveness and efficiency. Consistent monitoring and maintenance routines can help avoid unexpected downtimes and costly repairs.

| Issue | Impact on Performance | Recommended Solution | Frequency of Occurrence |

|---|---|---|---|

| Leakage in Seals | Decreased vacuum pressure, inefficient operation | Inspect and replace worn seals | High |

| Blockages in Piping | Reduced airflow and vacuum creation | Clear blockages and maintain clean pipes | Medium |

| Faulty Solenoid Valve | Compromised valve operation | Test and replace malfunctioning solenoid | Low |

| Incorrect Voltage Supply | Inconsistent operation of the valve | Verify electrical supply and connections | Medium |

| Wear and Tear | Overall system degradation | Schedule regular maintenance and part replacements | High |

To maximize the efficiency of your vacuum sequence valve, employing advanced technologies is crucial. Industry reports suggest that optimizing these valves can lead to performance improvements of up to 30%, translating to significant energy savings and reduced operational costs. One such technology is the integration of smart sensors. These sensors can provide real-time feedback on valve performance, allowing for immediate adjustments and preventing inefficiencies that could arise from traditional mechanical systems.

**Tip 1:** Invest in sensors that can monitor not only position but also flow rates and vacuum levels, improving your system's responsiveness and reliability.

Another promising advancement is the use of artificial intelligence (AI) to predict maintenance needs and failure points. According to a recent study, facilities that adopted AI-driven analytics reported a 25% increase in overall uptime. By anticipating issues before they become critical, operators can perform maintenance during planned downtimes rather than facing unplanned outages.

**Tip 2:** Implement predictive maintenance schedules using AI tools for a more proactive approach, ensuring your vacuum sequence valves are always operating at peak efficiency.

Upgrading to materials resistant to wear and corrosion can also enhance valve longevity and performance, as highlighted in the latest materials science reports, which indicate a 40% increase in lifespan for valves incorporating advanced composite materials over standard metals.

**Tip 3:** Evaluate your current materials and consider transitioning to high-performance composites to extend the service life of your valves and reduce replacement costs.