Leave Your Message

In the industrial sector, ensuring safety and operational efficiency is paramount, particularly when dealing with pressure relief in equipment and facilities. Emergency Relief Vents (ERVs) play a critical role in preventing hazardous overpressure conditions, which can lead to catastrophic failures. According to a recent industry report by the National Fire Protection Association, improper pressure management contributes to nearly 30% of industrial accidents, underscoring the need for reliable emergency relief solutions. Selecting the best Emergency Relief Vent for your specific industrial application is not merely a matter of compliance; it is a proactive measure to safeguard workers, equipment, and the environment. This blog will guide you through key considerations and best practices in choosing an ERV that meets the stringent safety requirements and operational demands of your facility.

Emergency relief vents play a crucial role in maintaining safety within industrial environments, particularly in sectors such as oil and gas, chemicals, and manufacturing. According to a report by the National Fire Protection Association (NFPA), approximately 54% of industrial fires are attributed to pressure buildup, underscoring the need for reliable relief systems. These vents are designed to mitigate excessive pressure during emergencies, thereby preventing catastrophic equipment failures, explosions, or hazardous material releases.

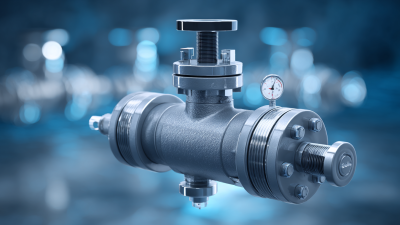

The proper selection of emergency relief vents is vital for optimizing operational safety. A study from the American Society of Mechanical Engineers (ASME) highlights that using undersized or improperly calibrated vents can lead to severe accidents, with costs in damages exceeding millions of dollars. As industries continuously adapt to increasing production demands and evolving safety regulations, investing in high-quality emergency relief vents ensures compliance and enhances overall system integrity. By carefully evaluating specifications, including set pressure ratings and flow capacity, organizations can fortify their defenses against potential industrial disasters.

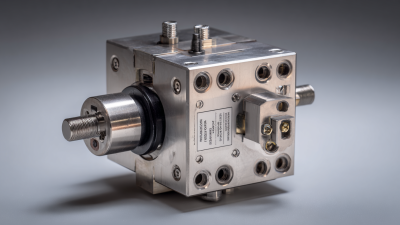

When selecting the best emergency relief vent for your industrial needs, it’s essential to consider several key factors. First, the specific application and environment in which the vent will be used play a significant role. Different industries may have varying regulations and safety standards that must be adhered to, making compliance a priority in your selection process. Additionally, the nature of the materials and gases involved will dictate the vent's sizing and materials, as they need to withstand specific pressures and temperatures.

Another crucial factor is the vent's design and functionality. Just as advancements in helmet technology have led to the development of lightweight yet protective options, emergency relief vents can also benefit from innovative designs. Look for vents that offer reliable performance with minimal maintenance requirements. Features such as corrosion resistance, easy installation, and integration capabilities with existing systems can enhance efficiency and safety in your operations. By carefully evaluating these key factors, you can ensure that you select the most suitable emergency relief vent for your industrial applications.

| Factor | Description | Considerations |

|---|---|---|

| Flow Capacity | The maximum flow rate that the vent can handle during an emergency. | Ensure it meets or exceeds your system's maximum expected flow. |

| Set Pressure | The pressure at which the vent will activate to relieve excess pressure. | Choose a set pressure suitable for your system's operating conditions. |

| Material Compatibility | The ability of the vent material to resist corrosion and wear based on the environment and fluids handled. | Select materials compatible with the chemicals in your process. |

| Size and Dimensions | The physical size of the vent, which must fit within existing space constraints. | Ensure the vent dimensions comply with installation space. |

| Maintenance Requirements | The frequency and complexity of maintenance needed to keep the vent operational. | Select a vent that minimizes downtime during maintenance. |

| Regulatory Compliance | Adherence to local, national, and international standards and regulations. | Confirm that the vent meets all necessary regulatory requirements. |

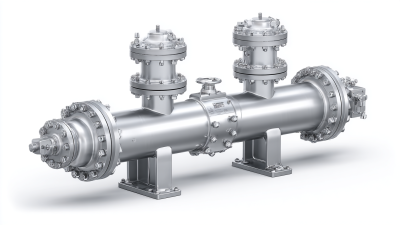

In today's industrial landscape, the selection of the right emergency relief vent (ERV) is critical for maintaining safety and regulatory compliance. Various types of ERVs are available, each designed for specific applications. For instance, pressure relief vents are commonly used in chemical processing facilities to prevent overpressurization during exothermic reactions. According to a report by the American Institute of Chemical Engineers (AIChE), about 70% of chemical facility incidents can be traced back to pressure control failures, underscoring the importance of effective relief systems.

When it comes to emergency relief vents, many misconceptions can lead to ineffective safety measures in industrial settings. One prevalent myth is that all relief vents are the same. In reality, the design of an emergency relief vent must align with the specific operational requirements of a facility. According to a recent industry report, improperly sized or configured vents can lead to equipment failure and catastrophic incidents, reminding us of historical events such as the Three Mile Island accident. This incident underscored the critical importance of proper vent design and function in reactor safety, illustrating how oversights can have dire consequences.

Another common misconception is that the installation of emergency relief vents can be an afterthought. This notion fails to recognize that these vents are integral to a facility's safety architecture. As per standards set by industry authorities, effective emergency relief systems should undergo regular testing and maintenance to ensure reliability during a crisis. Neglecting this aspect not only exposes facilities to risks but can also result in compliance issues, potentially leading to legal penalties and operational downtimes. Investing in the right emergency relief vent and understanding its role is essential for both compliance and safety in industrial operations.

When it comes to the installation and maintenance of emergency relief vents in industrial settings, adhering to best practices is crucial for ensuring safety and efficiency. One of the primary considerations is the design of the pressure-relief system. Recent developments in calculation methods and updates to industry codes and standards are pivotal in addressing deficiencies that have emerged in past designs. Ensuring that the relief vents are appropriately sized and located reduces the risk of overpressure situations, safeguarding both personnel and equipment.

Regular maintenance of relief vents is equally important to ensure that they function as intended during emergencies. Routine inspections should focus on checking for blockages, corrosion, or any signs of wear that could impair the vent's operation. Furthermore, training personnel in proper maintenance techniques, including the documentation of inspection results and repairs, fosters a proactive approach to safety. By cultivating a culture of adherence to best practices, industrial facilities can enhance their resilience against unforeseen pressure fluctuations, thereby protecting assets and maintaining operational integrity.