Leave Your Message

In the storage industry, safety and efficiency are paramount, particularly when dealing with volatile substances. A critical component in enhancing both aspects is the Tank Flame Arrestor, which serves as a vital safety device designed to prevent flames from propagating back into storage tanks. According to the National Fire Protection Association (NFPA), incidents related to flammable liquids account for over 20% of industrial fires. Therefore, selecting the right Tank Flame Arrestor is crucial, as it can significantly reduce the risk of catastrophic events while ensuring optimal operational efficiency. Reports from the International Society of Automation highlight that proper flame arrestor installation and maintenance can minimize hazardous incidents by as much as 50%. This blog aims to provide a comprehensive guide on how to select the appropriate Tank Flame Arrestor, ensuring that your storage facility remains safe and compliant with industry standards.

Tank flame arrestors play a crucial role in safety systems within storage facilities, acting as a barrier against the propagation of flames and explosion risks associated with flammable vapors. These devices function by slowing down and cooling down any flame that may travel through vent lines, preventing it from reaching the internal atmosphere of the tank. This is particularly vital in environments where volatile chemicals are stored, as even a small ignition source can lead to catastrophic incidents.

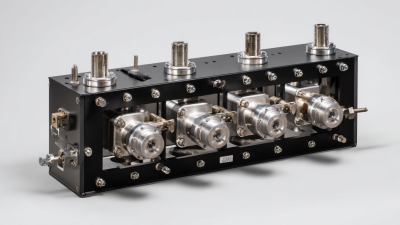

Understanding the functionality of tank flame arrestors involves recognizing their design and operational mechanisms. Typically constructed from materials that can withstand high temperatures and corrosive environments, flame arrestors consist of a series of metal plates or mesh that disrupt the flame front while allowing vapors to escape. Their effectiveness relies not only on proper installation but also on regular maintenance to ensure that they remain free from blockages and degradation. By integrating reliable flame arrestors into storage facility safety systems, businesses can significantly mitigate risks, ensuring both personnel safety and operational efficiency.

When selecting a tank flame arrestor, several key factors must be evaluated to ensure both safety and operational efficiency. One critical aspect is the type of service the flame arrestor will be used in; for instance, storage facilities handling volatile organic compounds (VOCs) require units designed to handle specific pressures and temperatures. According to the NFPA (National Fire Protection Association), improper equipment selection can lead to dangerous flare-ups, with incidents costing the industry an estimated $1.7 billion annually due to property damage and operational downtime.

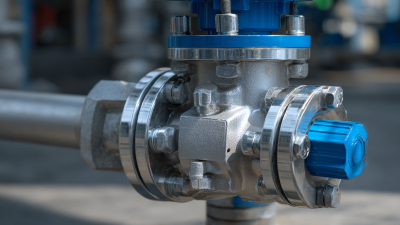

Another important consideration is the flow capacity of the flame arrestor. Industry standards recommend a minimum flow area based on the tank size and the expected vapor release rates. The American Petroleum Institute's API 2000 guidelines stress that undersized devices may not effectively mitigate flames, risking catastrophic failures. Furthermore, the material compatibility with the stored substance is crucial; non-corrosive materials such as stainless steel or special alloys can provide resistance against the harsh environments typically found in storage facilities, extending the longevity and reliability of the arrestor system.

When selecting a flame arrestor for storage facilities, it is crucial to understand the various types available and how they cater to different safety needs. The most common types include deflagration arrestors, detonation arrestors, and combination units. According to the National Fire Protection Association (NFPA), deflagration arrestors are designed to prevent fast-moving combustion from igniting flammable vapors, making them ideal for low-pressure systems often found in chemical storage. In contrast, detonation arrestors are built to withstand high-pressure blasts, suitable for environments where the risk of rapid pressure rise is higher, such as in gas processing plants.

When selecting a flame arrestor for storage facilities, it is crucial to understand the various types available and how they cater to different safety needs. The most common types include deflagration arrestors, detonation arrestors, and combination units. According to the National Fire Protection Association (NFPA), deflagration arrestors are designed to prevent fast-moving combustion from igniting flammable vapors, making them ideal for low-pressure systems often found in chemical storage. In contrast, detonation arrestors are built to withstand high-pressure blasts, suitable for environments where the risk of rapid pressure rise is higher, such as in gas processing plants.

Industry reports indicate that improper selection of flame arrestors can lead to catastrophic incidents, with the U.S. Chemical Safety Board highlighting that over 50% of industrial explosions could have been mitigated with proper installation and maintenance of safety equipment. For facilities dealing with hydrocarbon vapors, a combination unit might be the best option, offering protection against both deflagration and detonation, thus enhancing overall safety protocols. Each facility's unique characteristics, including the types of materials stored and the potential for vapor accumulation, will dictate the most appropriate flame arrestor type, underscoring the importance of thorough risk assessment during the selection process.

Regular maintenance of tank flame arrestors is crucial to ensure optimal performance and enhance safety in storage facilities.

To begin with, a routine inspection schedule should be established, checking for any signs of wear or corrosion.

Flame arrestors should be examined for blockages or contaminants that could hinder their operation.

Cleaning should be done in accordance with manufacturer guidelines, which often involve using appropriate solvents and tools to remove debris without damaging the unit.

Moreover, it is essential to perform functional tests periodically to confirm that the flame arrestors are performing as intended.

Recording the results of these tests can help track the efficiency of the arrestors over time.

Any discrepancies in performance should prompt immediate investigation and remediation. Additionally, keeping a detailed maintenance log can assist in identifying patterns or recurring issues, allowing for proactive adjustments before they escalate into potential safety hazards.

Implementing these best practices will not only extend the life of the flame arrestors but also safeguard the integrity of storage operations.

Selecting the right flame arrestor is crucial for ensuring regulatory compliance in storage facilities handling flammable substances. In light of recent legislative changes, devices that mitigate the risk of explosions are now mandatory for consumer containers of flammable liquids. This pushes businesses to not only enhance safety measures but also strive for compliance with evolving safety standards. A well-chosen flame arrestor can significantly reduce the risk of fire incidents while fulfilling legal obligations.

The integration of advanced flame arrestor technologies has been a key development in enhancing facility safety. For instance, recent advancements have set new industry standards that establish enhanced protocols for managing fire risks in storage environments. This is evident in new regulations from organizations focusing on safety in marine operations, where specific requirements are implemented to prevent detonations in environments that store volatile materials. Adopting these innovative solutions positions facilities not just as compliant entities but as leaders in safety and environmental responsibility.