Leave Your Message

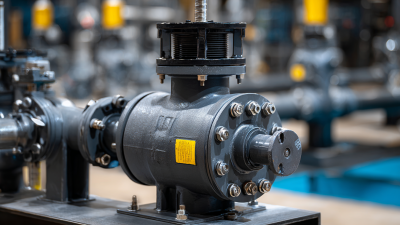

The effective use of the Varec Pressure Vacuum Relief Valve is crucial in various industries, especially in petrochemical applications. According to the American Petroleum Institute, improper venting can lead to hazardous incidents, highlighting the importance of these valves. Experts stress that “maintaining optimal performance of pressure vacuum relief valves is vital for operational safety,” says industry leader John Smith, who has over 20 years of experience in valve technology.

Operators often overlook the need for regular maintenance and proper installation of the Varec Pressure Vacuum Relief Valve. A report by the Chemical Engineering Safety Association indicates that 30% of valve failures stem from inadequate care. Regular checks can prevent excessive pressure buildup and ensure safe system operation. It's important to remember that even minor neglect can lead to severe consequences.

In addition, understanding the unique specifications and requirements of each system is essential. Half-hearted attempts at installation can lead to inefficiencies. Each environment has its challenges, and the Varec Pressure Vacuum Relief Valve must be tailored accordingly. Acknowledging the complexities in valve operations can lead to better decision-making and improved reliability in the field.

Pressure vacuum relief valves play a critical role in managing tank pressure. They allow air to enter or leave a tank, protecting it from pressure fluctuations. This is essential in maintaining the integrity of the tank structure. If the pressure increases too much, these valves open to release excess pressure. On the other hand, they also prevent contaminants from entering the tank.

Understanding how these valves work is vital for their effective use. Regular maintenance checks are necessary. Inspect for signs of wear and tear. If the valve doesn’t operate smoothly, it could lead to serious issues. Consider the environment where the valve operates. High temperatures or corrosive substances may impact its functionality.

Installation accuracy is crucial. Misalignment can hinder performance. Some users overlook this step, leading to inefficiencies. The valve must be positioned correctly to function as intended. Also, regular testing is often neglected. Testing ensures that valves respond correctly to pressure changes. If they fail during a critical moment, the results can be disastrous.

Understanding the key components of pressure vacuum relief valves is crucial for effective use. These valves generally consist of multiple parts: the body, the spring, the seat, and the lifting mechanism. Each part plays a significant role in maintaining safety and performance. According to industry reports, improper maintenance can lead to failures in 10% of valves, emphasizing the need for careful monitoring.

Regularly inspect the valve body for physical damage. Check the spring for stiffness and fatigue. This can prevent dangerous situations. About 5% of failures are attributed to worn springs. It's essential to replace them promptly to avoid valve malfunction.

Tips for effective usage include ensuring the valve is sized correctly for your application. Incorrect sizing can lead to over-pressurization or vacuum conditions. Always use certified components to ensure reliability. Regularly train your staff on valve operation and maintenance protocols. This not only enhances safety but also improves valve lifespan. Take note that neglecting preventive measures can lead to costly repairs or system shutdowns.

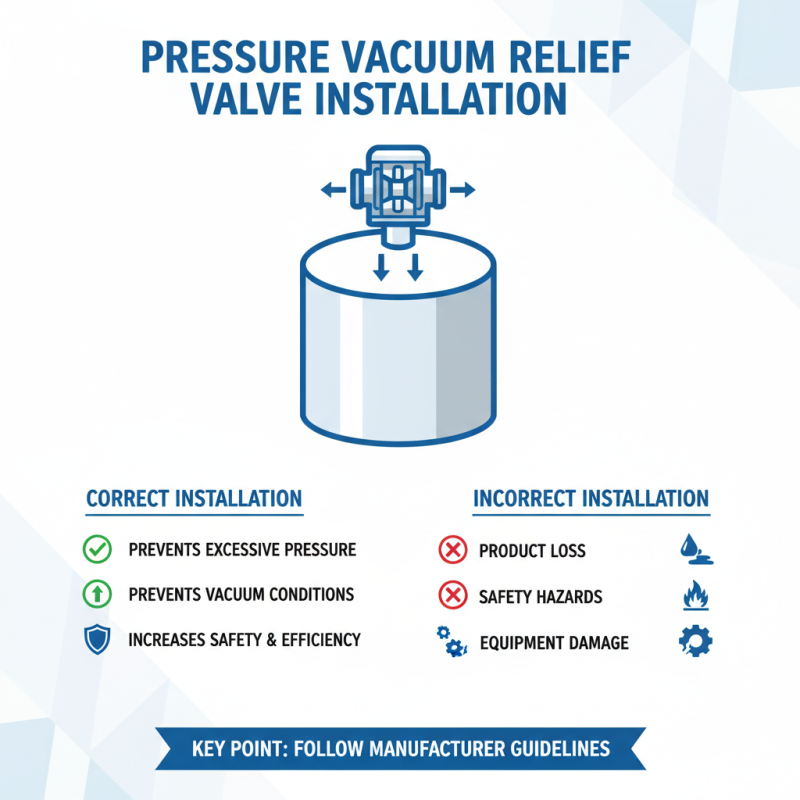

Installing a pressure vacuum relief valve requires careful attention. A well-installed valve prevents excessive pressure buildup and vacuum conditions in storage tanks. According to industry reports, improper installation can lead to significant product loss and safety hazards.

One tip is to ensure the valve is mounted correctly. Position it vertically to allow for optimal function. Also, check for obstructions in the surrounding area. Obstructions can impair airflow. Aim for at least 18 inches of clearance around the valve.

Another critical aspect is sealing the valve properly. Leaks can occur if seals are worn or incorrectly fitted. Regular maintenance checks are vital. Almost 30% of pressure relief system failures stem from poor sealing. Inspect seals for wear and replace them as necessary.

Finally, consider the environmental factors around the installation site. Temperature fluctuations can affect valve performance. Be mindful of potential corrosive materials in the vicinity. Evaluating these factors can help prevent future issues. Prioritize both safety and efficiency in your installation process.

Regular maintenance of pressure vacuum relief valves is crucial. It ensures these devices function effectively in preventing overpressure and vacuum conditions in storage tanks. Inspect valves regularly for visible signs of wear or damage. Look for leaks, rust, or any obstructions. These issues could indicate a failure that may lead to catastrophic results.

Cleaning is another vital aspect of maintenance. Dust and debris can accumulate and hinder valve operation. A simple wash with mild detergent can help. However, if you're unsure about how to clean them, consulting a professional is wise. After cleaning, check the valve’s seals and gaskets for wear. They should fit tightly; loose seals can lead to inefficiency.

Pressure tests should be carried out periodically. This can reveal hidden issues before they escalate. Not all valves respond the same way to pressure changes. Monitoring their performance helps identify any irregularities. Failing to perform these checks can result in costly repairs later on. Think about setting a maintenance schedule. It may require effort, but neglect can lead to safety hazards.

Pressure vacuum relief valves play a crucial role in maintaining safety in storage tanks. Common issues can arise if these valves are not regularly inspected. One typical problem is leakage. A valve may leak due to debris or wear and tear. Inspect the sealing surfaces. Cleaning or replacing seals can often solve this issue.

Another concern is improper opening pressure. The valve may not open at the specified pressure due to miscalibration. Regularly checking calibration settings is important. Adjusting them may be necessary to ensure proper operation. Don’t overlook rust or corrosion, either. These can weaken the valve body and result in failure.

Sometimes, a valve may stick. This may happen after long periods of inactivity. Regularly exercise the valve to avoid sticking. A sticky valve can lead to catastrophic failure. Inspecting and maintaining these valves doesn’t only prevent problems; it ensures safety. Frequent checks and quick resolutions to minor issues can save time and resources.