Leave Your Message

In today's gas management landscape, selecting the right Blanket Gas Regulator is essential for ensuring safety, efficiency, and compliance in various industrial applications. According to a recent market report by TechSci Research, the global gas regulator market is projected to reach $7.3 billion by 2026, growing at a CAGR of 4.2%. This growth is driven by the increasing need for precise pressure management in industries such as oil and gas, petrochemicals, and food and beverage sectors.

The Blanket Gas Regulator plays a critical role in maintaining the necessary pressure levels and preventing gas leaks, which can lead to costly downtime and safety hazards. With a myriad of options available, understanding the key features and specifications of these regulators is crucial for making an informed decision that aligns with your operational needs.

When selecting the right type of blanket gas regulator, it is essential to consider various factors that align with your specific needs. Blanket gas regulators are crucial for maintaining a consistent pressure in gas storage systems, ensuring optimal performance and safety.

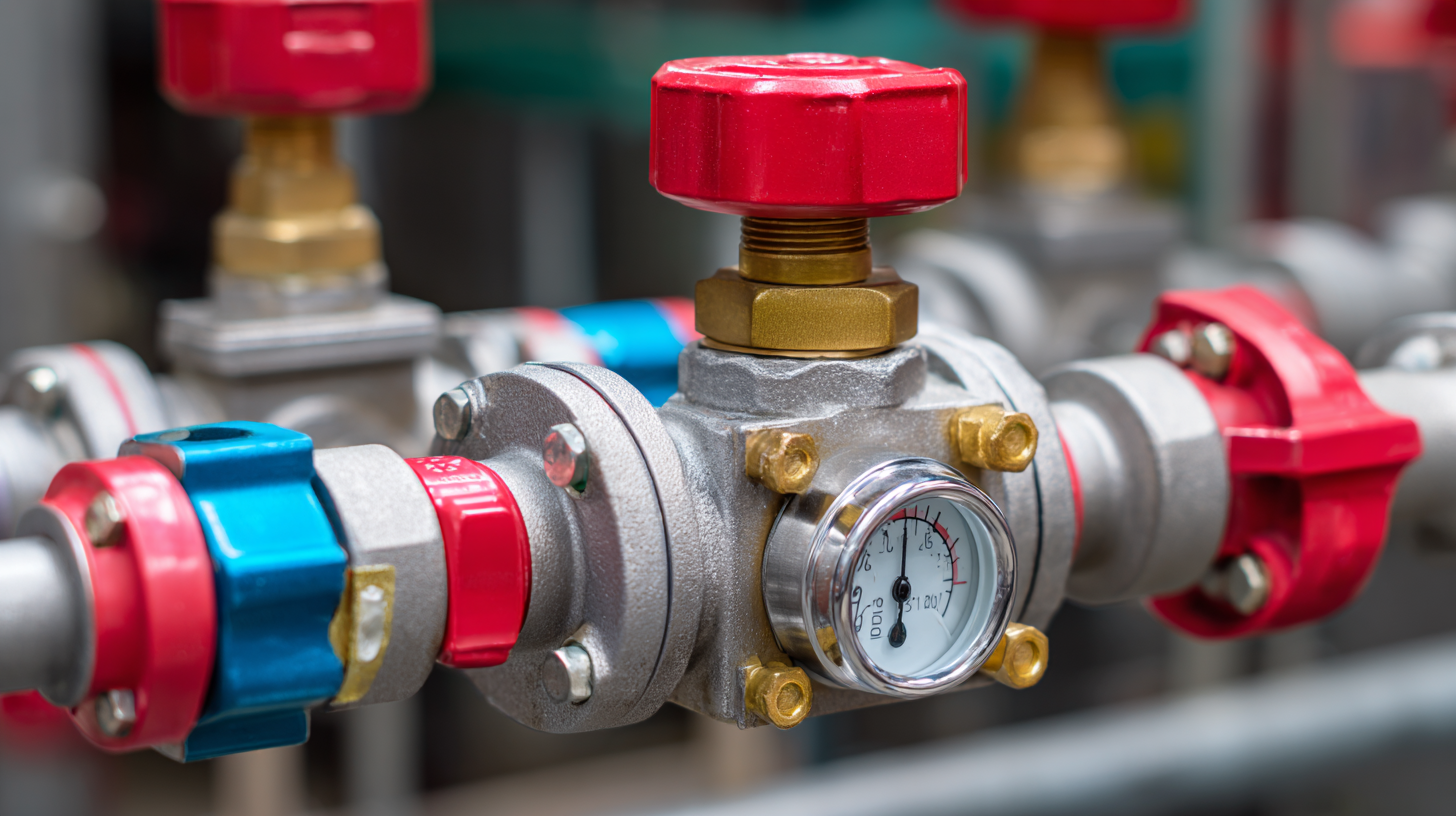

There are several types available, including high-pressure, low-pressure, and dual-stage regulators, each designed for different applications. Understanding the pressure and flow requirements of your system can help you determine which type is suitable for your operations.

There are several types available, including high-pressure, low-pressure, and dual-stage regulators, each designed for different applications. Understanding the pressure and flow requirements of your system can help you determine which type is suitable for your operations.

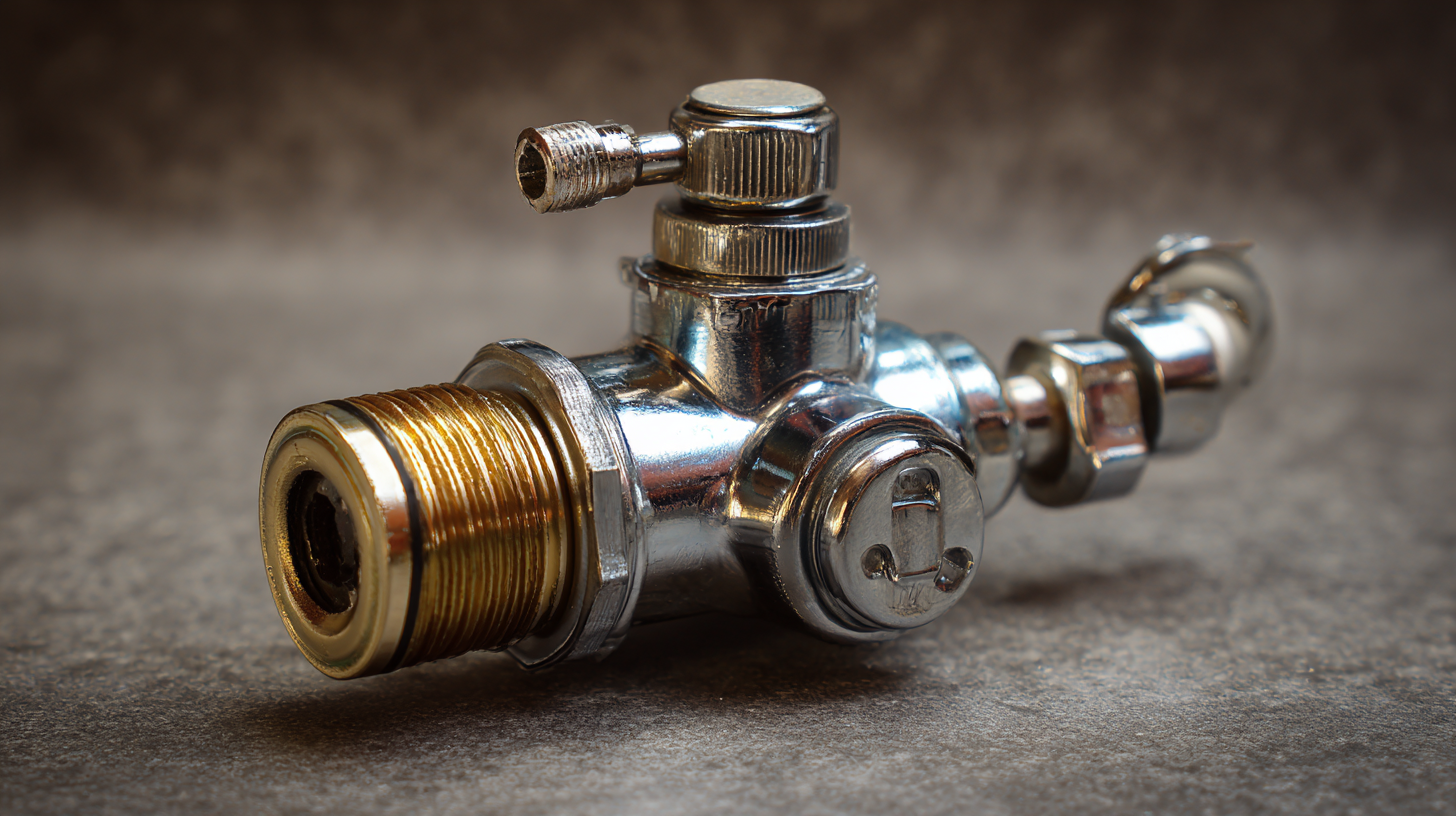

Additionally, compatibility with the gases being used is another critical aspect to evaluate. Some regulators are designed for specific gases, and selecting the right one can prevent accidents and enhance efficacy. Features such as pressure gauges, shut-off valves, and relief mechanisms also play a vital role in the functionality of a gas regulator. By carefully analyzing your operational environment and regulatory requirements, you can choose a blanket gas regulator that offers reliability and maximizes your system's efficiency.

When selecting a blanket gas regulator, understanding the key specifications can significantly enhance its performance for your specific application. One critical factor to consider is the pressure rating, which should align with the operational requirements of your system. Industry standards indicate that blanket gas regulators often operate optimally within a pressure range of 10 to 300 psi. Choosing a regulator that accommodates these specifications is essential for maintaining stable gas delivery and preventing fluctuations that can lead to process inefficiencies.

Another vital specification is the material used in the regulator's construction, which affects durability and resistance to various gases. According to a report by the Gas Processors Association, regulators made from stainless steel or high-grade brass exhibit superior longevity and corrosion resistance, particularly in aggressive environments. Additionally, ensure the regulator features an adequate flow capacity, often measured in SCFM (Standard Cubic Feet per Minute), to support the demands of your operations, which can vary significantly depending on the application. Selecting a model that matches these criteria is paramount for achieving optimal performance and reliability in your gas handling processes.

When selecting a blanket gas regulator, it’s essential to consider the various brands that dominate the market. Leading manufacturers such as Matheson, Airgas, and Yamada consistently deliver high-quality products tailored to specific needs in industries ranging from food processing to pharmaceuticals. Matheson is renowned for its robust designs and reliable performance, making it an excellent choice for applications requiring precise gas pressure control. In contrast, Airgas offers a wider range of options, catering to both large-scale operations and smaller facilities, which provides flexibility for users with diverse requirements.

Yamada, on the other hand, has made a name for itself with its innovative pressure management solutions that prioritize safety and efficiency. Their products are often favored in critical environments where the integrity of gas supply is paramount. Overall, thorough research into these top brands can help you identify the best blanket gas regulator that aligns with your operational needs while ensuring reliability and safety. Emphasizing the importance of quality and performance, this analysis serves as a valuable starting point for making an informed decision.

When selecting a blanket gas regulator, understanding safety standards and compliance is paramount. Various regulatory bodies, such as the American National Standards Institute (ANSI) and the Occupational Safety and Health Administration (OSHA), establish essential guidelines to ensure that gas regulators perform safely and efficiently. These standards cover aspects like pressure regulation, materials used, and design features to prevent leaks or malfunctions. By adhering to these regulations, manufacturers create products that not only meet industry expectations but also prioritize user safety.

In addition to compliance with established standards, it's crucial for users to verify that the blanket gas regulator they choose has been rigorously tested and certified for quality. Look for labels and documentation indicating compliance with relevant standards, such as those from the Canadian Standards Association (CSA) or the Underwriters Laboratories (UL). These certifications denote that the regulator has passed stringent safety evaluations. Prioritizing these factors when selecting a gas regulator not only ensures regulatory compliance but also enhances overall safety in operations, reducing the risk of accidents and providing peace of mind for users.

| Feature | Description | Safety Standard Compliance | Regulatory Body |

|---|---|---|---|

| Material | High-grade lightweight aluminum | Yes | American National Standards Institute (ANSI) |

| Pressure Range | 0-30 psi | Yes | National Fire Protection Association (NFPA) |

| Flow Rate | Up to 10 NM³/h | Yes | Underwriters Laboratories (UL) |

| Temperature Range | -40°F to 150°F | Yes | Gas Appliance Manufacturers Association (GAMA) |

| Certification | ISO 9001 | Yes | International Organization for Standardization (ISO) |

When it comes to blanket gas regulators, proper maintenance is key to ensuring their longevity and efficiency. Regular inspections play a crucial role in this process. Check for leaks, wear and tear, and any signs of corrosion at least once a month. This proactive approach can help identify potential issues before they escalate, saving you time and money in the long run.

Another important aspect of maintenance is cleaning the regulator. Dust, dirt, and other contaminants can accumulate and affect performance. Use a soft cloth and appropriate cleaning solution to wipe down the exterior regularly. Additionally, be sure to replace any filters as recommended by the manufacturer to prevent clogging and ensure optimal gas flow.

Calibration is another vital tip that should not be overlooked. A properly calibrated regulator ensures that the pressure remains consistent, providing reliable performance. Schedule routine checks and adjustments as needed to maintain accurate pressure levels. By implementing these maintenance tips, you can extend the life of your blanket gas regulator while enhancing its efficiency.

This chart compares the efficiency ratings of various blanket gas regulators. The ratings are based on performance data collected from standard operational conditions. Proper selection and maintenance of a gas regulator can significantly affect overall efficiency and lifespan.