Leave Your Message

In the realm of industrial safety, the role of Deflagration Type Flame Arresters (DTFA) cannot be overstated. As highlighted by renowned safety expert Dr. John H. Smith, “Understanding the mechanics of Deflagration Type Flame Arresters is crucial for effective hazard mitigation in high-risk environments.” This statement underscores the importance of comprehending how these devices function to prevent flame propagation in potentially explosive atmospheres.

Deflagration Type Flame Arresters serve as a vital line of defense against flames that can travel through venting systems, posing significant risks to personnel and infrastructure. By effectively disrupting flame fronts, these devices provide a crucial safety barrier in various industries, including petrochemical, manufacturing, and food processing. As the industry continues to evolve, it becomes increasingly essential for professionals to stay informed about the latest technologies and safety standards associated with DTFA.

An in-depth understanding of Deflagration Type Flame Arresters not only enhances operational safety but also contributes to regulatory compliance. The knowledge gained through rigorous training and research can significantly mitigate the risks associated with explosive atmospheres, ensuring safer working conditions for all involved. As we delve into the ultimate tips for effectively understanding DTFA, we will explore essential design principles, maintenance practices, and emerging technologies that shape the future of industrial safety.

Deflagration is a combustion process characterized by the low-speed propagation of a flame, often seen in industrial applications involving flammable gases. Understanding this phenomenon is crucial for the design and implementation of flame arresters, especially deflagration type flame arresters. These devices are engineered to prevent flame propagation in piping systems by quenching the flame front, thereby safeguarding equipment and personnel from potential hazards. According to the American Institute of Chemical Engineers (AIChE), a staggering 70% of industrial fires are linked to flammable gas leaks, underscoring the significance of effective flame arresters in risk management strategies.

The effectiveness of deflagration flame arresters is often measured through various performance metrics, including the quenching distance— the distance over which the flame can still propagate after interacting with the device. Research published in the Journal of Loss Prevention in the Process Industries indicates that optimizing the design of these arresters can lead to a drastic reduction in the transmission of flame, with some designs achieving up to 99% flame propagation suppression. Furthermore, the National Fire Protection Association (NFPA) emphasizes the critical role these devices play in maintaining operational safety standards and compliance, particularly in facilities that handle explosive atmospheres. Understanding the principles of deflagration not only facilitates better design but also enhances training programs for personnel tasked with maintaining safety protocols in high-risk environments.

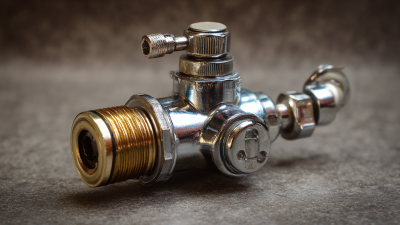

Deflagration-type flame arresters play a crucial role in preventing the propagation of flames in industrial applications. Their primary function is to allow gas or vapor to pass through while blocking flames, making them essential safety devices in processes involving flammable substances. Key design features of these arresters include the use of a series of chambers and baffles that create turbulence, effectively slowing down the flame front and dissipating its energy. This design not only minimizes the risk of a fire spreading but also ensures that any flame that does enter the arrester is extinguished before it can travel further into ductwork or storage areas.

Another significant aspect of deflagration-type flame arresters is their material construction. They are often made from robust, corrosion-resistant materials that can withstand high temperatures and pressures. This ensures longevity and reliability in the field, where environmental conditions can vary greatly. Additionally, the size and configuration of the vent openings are meticulously designed. These openings are strategically placed to maintain optimal flow while preventing any flame from escaping. Overall, understanding these key design features helps in both selecting the appropriate flame arrester for specific applications and maintaining safety standards in facilities that handle flammable materials.

| Feature | Description | Functionality | Material | Application |

|---|---|---|---|---|

| Flame Arresting Element | Prevents flames from propagating | Flame suppression | Stainless Steel | Gas processing facilities |

| Pressure Drop | Minimal pressure loss through the arrester | Efficiency in operation | Carbon Steel | Chemical processing |

| Installation Orientation | Vertical or horizontal installation options | Versatile installation | Aluminum | Oil and gas applications |

| Temperature Rating | Designed for high and low-temperature applications | Safety in extreme conditions | Alloy Materials | Pharmaceutical industries |

| Compliance Standards | Complies with international safety standards | Regulatory adherence | Various materials | Waste management facilities |

When considering the application of deflagration type flame arresters in various industries, it is crucial to understand the regulatory landscape that governs their use. Industry standards, such as those established by organizations like the National Fire Protection Association (NFPA) and the American Petroleum Institute (API), provide guidelines on the design, testing, and installation of flame arresters. These standards aim to enhance safety by ensuring that flame arresters are effective in preventing the propagation of flames in flammable gas and vapor systems. Compliance with these regulations is not only essential for safety but also for achieving operational efficiency in facilities that handle volatile substances.

Moreover, adhering to the established standards allows for uniformity in the manufacturing and performance of flame arresters. Regulations address critical aspects such as material specifications, testing methodologies, and maintenance protocols, ensuring that flame arresters can function reliably under various conditions. Industries such as petrochemicals, pharmaceuticals, and food processing must stay up-to-date with these regulations to mitigate risks associated with explosive atmospheres. By implementing the best practices outlined in these industry standards, organizations can foster a culture of safety and resilience in their operations, reducing the likelihood of fire incidents and enhancing overall workplace safety.

In industrial settings, the effectiveness of deflagration flame arresters is critical for ensuring safety during operations involving flammable materials. Case studies have shown that the installation of these devices significantly reduces the risk of fire and explosion. For instance, a 2022 industry report by the National Fire Protection Association indicated that facilities employing flame arresters saw a 40% decrease in fire-related incidents compared to facilities without them. This highlights the importance of integrating flame arresters within safety management systems in various sectors, such as chemical manufacturing and oil processing.

To enhance the understanding of deflagration flame arresters, it is essential to consider specific tips. First, proper sizing and installation are crucial. Utilizing a flame arrester that is appropriately rated for the specific application can drastically improve its performance. Second, regular maintenance and inspections should be a standard practice. A study conducted by the European Process Safety Centre found that 60% of flame arresters inspected over five years showed significant wear or blockage that could affect their functionality. Third, training personnel on the operational principles and maintenance needs can further ensure that these devices work optimally, contributing to workplace safety.

These insights underscore that a strategic approach to flame arrester utilization, in conjunction with thorough training and maintenance protocols, can lead to enhanced safety outcomes across industrial environments. The ongoing commitment to safety through such measures is vital to protecting both people and property in industries where flammable gases and vapors are present.

Maintenance practices are critical for ensuring the optimal performance of deflagration type flame arresters. Regular inspection and maintenance routines can significantly enhance the reliability of these safety devices. A report from the National Fire Protection Association (NFPA) indicates that improper maintenance is a leading cause of system failures in industrial applications, which can lead to catastrophic consequences. To mitigate such risks, it is essential to follow industry guidelines for regular checks on critical components, including the inlet and outlet connections, sealing surfaces, and the condition of flame arresting media.

One vital maintenance practice involves conducting periodic flow tests to ensure that flame arresters are functioning correctly. According to research by the American Institute of Chemical Engineers (AIChE), effective flame arresters can reduce the risk of explosions by up to 90% when maintained properly. Operators should document all testing results and maintenance activities, which helps track performance over time and identifies any recurring issues. Additionally, cleaning the arresters on a scheduled basis is crucial, as accumulated dirt or debris can compromise their effectiveness, ultimately jeopardizing safety in hazardous environments. Regular training for personnel on maintenance procedures and potential risks can further uphold the integrity and functionality of flame arresters in various industrial settings.