Leave Your Message

In the realm of industrial safety and efficiency, the Varec Pressure Vacuum Relief Valve stands out as a critical component in protecting storage tanks and equipment from dangerous pressure variances. Industry expert Dr. Alice Thompson, a recognized authority on pressure management systems, emphasizes, "The Varec Pressure Vacuum Relief Valve not only safeguards equipment but also enhances operational reliability." This statement encapsulates the essence of these valves, highlighting their dual role in ensuring safety while promoting efficiency.

The inherent design of the Varec Pressure Vacuum Relief Valve allows for controlled pressure release and vacuum protection, thus preventing catastrophic failures in storage systems. As environments become more complex and demanding, these valves play an indispensable role in maintaining balance within containment systems. Understanding their key features and benefits is crucial for industries that require optimal performance and stringent safety standards.

As we delve deeper into the functionalities and advantages of the Varec Pressure Vacuum Relief Valve, it becomes evident that these valves are not merely components but essential instruments that contribute significantly to operational integrity and safety protocols in various industrial applications.

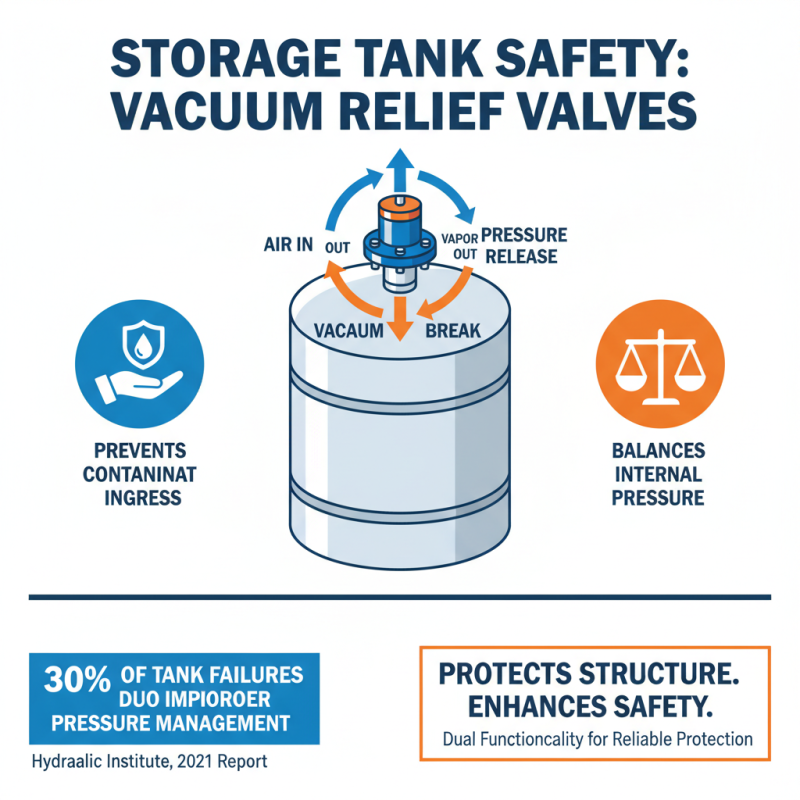

Varec pressure vacuum relief valves play a crucial role in maintaining the integrity and safety of storage tanks and other pressure-sensitive environments. One of the key features of these valves is their ability to balance the internal pressure of the tank while preventing the ingress of contaminants. This dual functionality is vital in preventing dangerous over-pressurization or vacuum conditions that could lead to structural failure. According to a 2021 industry report by the Hydraulic Institute, nearly 30% of storage tank failures are attributed to improper pressure management, underscoring the importance of reliable pressure vacuum relief systems.

Another significant feature of these valves is their rapid response time. Advanced engineering designs facilitate swift opening and closing, allowing the system to react promptly to pressure fluctuations. In high-demand sectors such as petrochemicals and pharmaceuticals, where precise environmental controls are essential, having a valve that can quickly adapt to changing conditions provides substantial operational advantages. A recent study from the American Society of Mechanical Engineers highlighted that improved valve responsiveness can reduce downtime by up to 15%, thus enhancing overall efficiency and productivity in industrial operations.

Additionally, Varec-type valves often include features like corrosion-resistant materials and customizable settings to meet specific application requirements, which further enhance their reliability and lifespan. The importance of selecting valves designed to withstand harsh conditions cannot be overstated, as failure to do so can lead to significant financial losses and even environmental hazards. Data from the Energy Information Administration suggests that industries with robust pressure management systems can reduce maintenance costs by as much as 20%, emphasizing the financial benefits of investing in high-quality pressure vacuum relief valves.

Varec Pressure Vacuum Relief Valves play a crucial role in enhancing operational safety and efficiency. One of the primary benefits of these valves is their ability to protect storage tanks from overpressure and vacuum conditions. By allowing or restricting airflow as needed, they prevent structural damage to tanks, which can result from expansions or contractions caused by temperature fluctuations or changes in liquid levels.

Moreover, these valves contribute to the overall integrity of the storage system by minimizing the release of vapors and emissions into the atmosphere. This not only helps companies comply with environmental regulations but also enhances workplace safety by reducing the risk of hazardous vapor accumulation. Additionally, Varec Pressure Vacuum Relief Valves are designed for reliability and ease of maintenance, ensuring that operations can continue smoothly without prolonged downtime for repairs or replacements. Their robust construction and effective performance standards make them a valuable asset for any storage operation, providing peace of mind in the management of volatile substances.

Pressure vacuum relief valves are critical components in many industrial applications, playing a vital role in maintaining safety and operational efficiency. Understanding the mechanism of these valves allows users to appreciate their functionality in preventing vacuum conditions and overpressure scenarios that can lead to catastrophic failures. These valves operate by automatically opening at predetermined pressure thresholds, allowing air to enter or exit the tank. This ensures that the pressure levels remain within safe limits, which is essential for preventing structural failure of storage vessels.

Tips for selecting the right pressure vacuum relief valve include considering the specific application and the fluid properties involved. It’s crucial to choose a valve that can handle the pressure ranges and flow rates of your system. Regular maintenance and inspections are also recommended to ensure optimal performance, as debris or wear can hinder the valve's operation. Implementing a routine check for leakage or wear can extend the lifespan of the valve and enhance system reliability.

In addition, understanding the environmental conditions where the valve will be installed is essential. Factors such as temperature, humidity, and exposure to chemicals can influence the material choice and overall design of the valve. Ensuring compatibility will provide better durability and reduce the risk of failures caused by external factors.

| Feature | Description | Benefit |

|---|---|---|

| Pressure Relief | Allows excess pressure to be safely released. | Prevents tank rupture and ensures safety. |

| Vacuum Relief | Protects against negative pressure conditions. | Maintains structural integrity of tanks. |

| Durable Construction | Made with high-quality materials. | Ensures long-lasting performance and reliability. |

| Easy Installation | Designed for straightforward setup. | Reduces installation time and labor costs. |

| Customizable Options | Available in various sizes and configurations. | Meets specific application requirements effectively. |

Pressure vacuum relief valves are critical components in various industries, ensuring safe and efficient operations while protecting storage tanks and process systems. These valves are designed to mitigate pressure fluctuations during filling and emptying processes, allowing for controlled venting.

Their applications span across industries such as oil and gas, chemical manufacturing, pharmaceuticals, and even food processing, where the integrity of volatile or sensitive substances is paramount.

In the oil and gas sector, these valves play a vital role in preventing tank overpressure and vacuum conditions, which could lead to equipment failures or environmental hazards. In chemical manufacturing, they help manage vapors and maintain safe conditions during the transfer and storage of chemicals. Similarly, in pharmaceuticals and food processing, maintaining the purity of the products during storage and transport is essential.

Properly functioning pressure vacuum relief valves not only enhance safety but also improve operational efficiency across these critical sectors, making them indispensable in modern industrial operations.

Maintenance and safety considerations for pressure vacuum relief valves are crucial for ensuring their effective operation in various industrial applications.

Regular inspections and routine maintenance help identify any wear and tear that may compromise the valve's functionality. Operators should establish a maintenance schedule that includes checking sealing surfaces, springs, and any associated components for signs of corrosion or damage.

Additionally, ensuring that the valve operates smoothly without obstructions is essential in preventing hazardous situations.

Training personnel on the proper operation and maintenance protocols is also vital. Technicians should be equipped with the knowledge to detect early signs of malfunction and understand the importance of immediate corrective actions.

Safety measures such as appropriate personal protective equipment (PPE) should be enforced when conducting maintenance tasks.

Clear operational guidelines can minimize risks and enhance safety, ensuring that the pressure vacuum relief valves function effectively in protecting storage tanks and other equipment from pressure fluctuations.

Implementing these maintenance and safety considerations not only extends the lifespan of the valves but also protects the overall integrity of the containment systems.