Leave Your Message

In today's industrial landscape, ensuring safety and efficiency in operations is paramount, particularly when dealing with high-pressure systems. Emergency Relief Valves (ERVs) play a critical role in safeguarding equipment and personnel by managing excess pressure and preventing catastrophic failures. According to a report by MarketsandMarkets, the global market for ERVs is anticipated to reach USD 5.7 billion by 2026, reflecting a growing recognition of their importance in mitigating risks associated with industrial processes. These advanced solutions not only enhance operational safety but also optimize system performance, thus reducing downtime and maintenance costs. With industries increasingly adopting automation and process optimization, the implementation of state-of-the-art Emergency Relief Valve technology is essential for achieving compliance with safety regulations while maximizing production efficiency.

Emergency relief valves (ERVs) play a crucial role in maintaining safety within industrial operations. They act as critical fail-safes designed to release excess pressure in systems that handle hazardous materials, preventing catastrophic failures such as explosions or toxic releases. The recent hazardous ammonia release incident on July 31, 2024, highlighted the necessity for advanced ERV solutions that can efficiently manage pressure surges and protect both personnel and the environment. By integrating sophisticated design and technology into ERVs, industries can significantly enhance their emergency preparedness and response capabilities.

Furthermore, the complexities of industrial operations necessitate a deeper understanding of the specific requirements for ERVs in various settings, including chemical and petrochemical plants. The recent updates from the US Chemical Safety and Hazard Investigation Board serve as a reminder of the importance of rigorous safety protocols and the efficient functioning of emergency relief systems. Ensuring that ERVs are not only compliant with safety regulations but also fitted with the latest technological advancements is fundamental in minimizing risks and optimizing operational efficiency. As industries continue to evolve, the proactive enhancement of emergency relief valve solutions will be vital to safeguarding both human lives and valuable resources.

In the industrial sector, ensuring safety while maintaining operational efficiency is paramount. Advanced emergency relief valve solutions play a critical role in mitigating risks associated with pressure system failures. When evaluating these valves, there are several key features to consider. One of the most important aspects is the response time; high-performance relief valves can react in less than a second, providing essential protection against catastrophic failures. According to a report by the American Society of Mechanical Engineers (ASME), facilities that utilize optimized emergency relief valves have seen a 30% reduction in safety incidents.

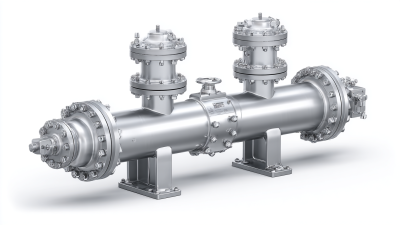

In addition to response time, durability is another critical feature. Valves constructed from high-grade materials, such as stainless steel or duplex steel, ensure longevity and reliability, particularly in harsh environments. Data from the National Safety Council indicates that industries employing high-quality relief systems could reduce maintenance costs by up to 25%.

Tip: Regularly inspect and maintain emergency relief valves to ensure they function correctly during an emergency. Implementing a scheduled testing routine can detect any potential issues early, further enhancing safety and operational efficiency.

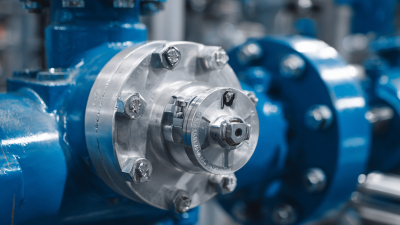

Implementing effective emergency relief valve systems is crucial for maximizing safety and efficiency in industrial operations. One key strategy involves conducting a thorough risk assessment to identify potential failure scenarios and pressure surges that could lead to hazardous situations. By understanding these risks, operators can select appropriate valve types and sizes that align with the specific needs of their facility. Moreover, integrating advanced technology, such as smart monitoring systems, can provide real-time data on system performance, enabling proactive maintenance and quicker response times in emergencies.

Another important approach to implementing emergency relief valve systems is ensuring proper training and education for personnel. Staff should be well-versed in the operational aspects of the valves, including their function, maintenance schedules, and emergency procedures. Regular drills and simulations can enhance readiness and familiarize team members with the protocols necessary to respond swiftly to unexpected events. Additionally, collaborating with valve manufacturers for tailored solutions and support can lead to the establishment of reliable systems that significantly reduce the risk of catastrophic failures while maintaining operational efficiency.

Emergency relief valves are critical components in maintaining safety within industrial operations, particularly in situations involving fire hazards. Regular maintenance and testing of these valves are essential in ensuring they function correctly during emergencies. Implementing best practices such as routine inspections, replacing worn parts, and verifying calibration can greatly enhance the reliability of these safety devices. It’s advisable to establish a rigorous schedule for testing that aligns with regulatory requirements and manufacturer guidelines, which fosters a proactive approach to fire safety.

Onboard inspections should encompass a comprehensive checklist, identifying at least 13 fire protection equipment items that require annual checks. These inspections not only help verify the operational status of emergency relief valves but also ensure that the entire fire protection system is functioning optimally. In high-risk environments, such as those found in industrial settings, the implementation of a systematic maintenance plan will significantly mitigate potential risks, maximizing both safety and operational efficiency. Consistent training and awareness among personnel about the importance of these practices further contribute to a safer work environment.

In the realm of industrial operations, the implementation of advanced emergency relief valve solutions has proven instrumental in enhancing both safety and efficiency. Case studies highlight notable success stories where companies have effectively minimized risks during emergency situations. For instance, a leading chemical manufacturing plant integrated state-of-the-art relief valves that feature automated monitoring and rapid response capabilities. This resulted in a significant reduction in overpressure incidents, safeguarding both personnel and equipment while ensuring uninterrupted production processes.

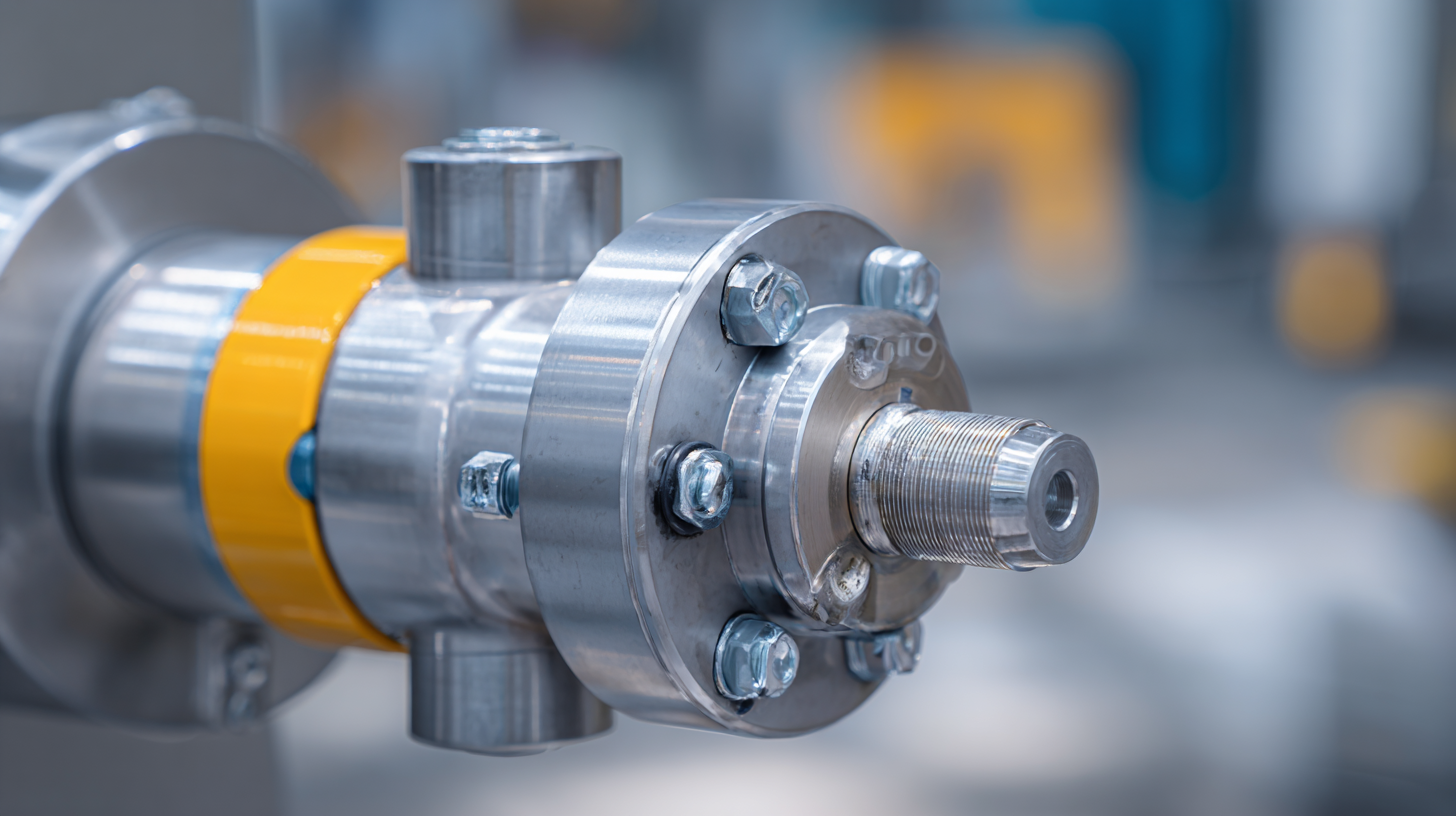

Another compelling case involves a refinery that experienced frequent maintenance issues due to outdated valve systems. By upgrading to modern emergency relief valves equipped with real-time data analytics, the facility achieved improved predictive maintenance schedules. This not only reduced downtime but also optimized operational efficiency. Employees reported heightened confidence in the safety measures implemented, fostering a culture of safety that translated into better performance metrics across the board.

These case studies underscore the critical role advanced emergency relief valves play in not only protecting assets but also enhancing the overall operational efficiency of industrial facilities.