Leave Your Message

In the world of fluid control, the pilot-operated diaphragm valve stands out for its efficiency and precision. A recent industry report suggests that these valves can reduce energy consumption by up to 30%, making them a vital choice for various sectors. Their design allows for better control over pressure, leading to improved process reliability.

However, it's important to acknowledge that not all installations benefit equally. In some cases, maintenance costs can rise due to their complexity. A report highlights that improper installation can lead to performance issues, emphasizing the need for skilled personnel. Despite these challenges, the overall advantages make pilot-operated diaphragm valves a preferred choice in many industries.

As companies strive for optimal performance, the pilot-operated diaphragm valve continues to gain traction. It offers flexibility in handling diverse media, which can be a game-changer in many applications. Yet, it's crucial to reflect on the integration process and ongoing maintenance. Ensuring that operators fully understand these systems is essential for maximizing their potential.

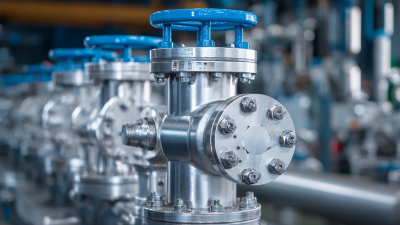

Pilot Operated Diaphragm Valves are innovative devices used to control fluid flow. They utilize a diaphragm that moves in response to pilot pressure. This design allows for precision and reliability in various applications. The mechanism is simple yet effective. As the pilot pressure changes, it either opens or closes the main valve. This creates a powerful, responsive system that can handle diverse conditions.

One of the key advantages is their ability to handle corrosive or abrasive fluids. The diaphragm separates the fluid from the actuator, providing excellent protection. Maintenance can be easier than with traditional valves. However, the system may require careful monitoring. Any leaks in the pilot system can affect overall performance. Understanding common issues is crucial for optimal operation.

They offer excellent flow control and can maintain low or high pressure. The versatility of these valves makes them suitable for many industries, including water management. Yet, installation demands attention to detail. Misalignment can lead to premature failure. Regular checks and adjustments might be necessary to ensure long-term success.

Pilot operated diaphragm valves offer significant advantages in various industries. Their design allows for precise control over fluid flow, making them ideal for applications requiring high accuracy. These valves feature a flexible diaphragm that reacts to pressure changes. This design minimizes the risk of leaks, ensuring that operations remain safe and efficient.

Additionally, pilot operated diaphragm valves are energy-efficient. They require less force to open and close the valve, reducing energy consumption. Their compact size can save space in installations, which is crucial in tight environments. The ability to use these valves with a wide range of fluids also enhances their versatility. Industries can operate with different media without extensive modifications.

One must consider the maintenance aspects. Although they are durable, issues can arise after extensive use. Regular inspections are necessary to ensure optimal performance. Moreover, the initial setup might require careful calibration, which can be time-consuming. Nevertheless, once properly configured, these valves demonstrate stable and reliable operation.

| Benefit | Description |

|---|---|

| 1. Accurate Control | Provides precise flow control through variable pressure settings. |

| 2. Reduced Leakage | Minimizes risk of leaks due to the diaphragm's sealing capability. |

| 3. Versatile Applications | Suitable for various media, including corrosive and viscous fluids. |

| 4. Easy Maintenance | Simplified design leads to easier access for maintenance and repair. |

| 5. Safety Features | Incorporates safety mechanisms that minimize operational risks. |

| 6. Consistent Performance | Delivers reliable functionality under varying conditions. |

| 7. Compact Design | Space-saving configuration ideal for limited spaces. |

| 8. Energy Efficiency | Reduces energy consumption through effective pressure modulation. |

| 9. Long Service Life | Designed for durability, decreasing the need for frequent replacements. |

| 10. Cost-Effective | Long-term savings through decreased maintenance and energy needs. |

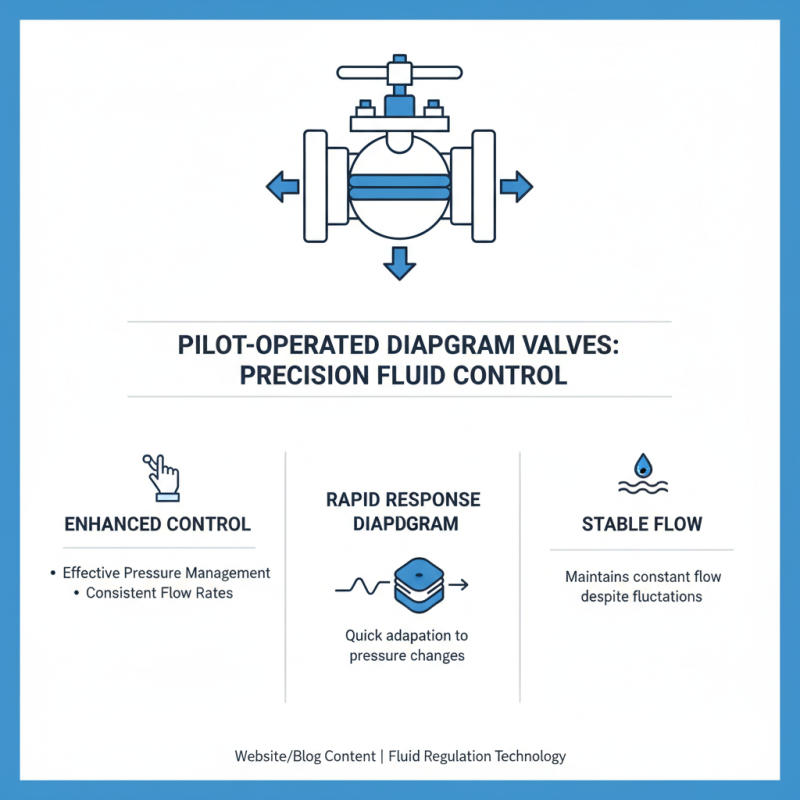

Pilot operated diaphragm valves provide enhanced control and precision in fluid regulation. Their design allows for effective pressure management. They use a diaphragm that responds quickly to varying pressures. This trait ensures consistent flow rates even under fluctuating conditions.

One key feature is their ability to handle varying fluid viscosities. This versatility improves operation in diverse systems. When using these valves, consider the fluid's properties. Matching the valve type with the process can lead to better performance.

Tips: Regular maintenance is crucial. Inspect the diaphragm for wear and tear. Periodic checks can prevent unexpected failures. Adequate training for operators can enhance overall system efficiency. Understanding how to fine-tune these valves improves flow control significantly.

Pilot operated diaphragm valves are known for their impressive durability and longevity. Unlike traditional valves, these designs feature a robust construction that can withstand high pressures and temperatures. The diaphragm is the key component here, made from resilient materials that resist wear and tear over time. This allows them to handle demanding applications without frequent maintenance.

Moreover, pilot operated valves utilize a unique mechanism that reduces stress on components. This leads to fewer breakdowns and longer service life. Their design minimizes leakage, which is crucial in maintaining systems efficiently. With fewer parts exposed to harsh conditions, there is less chance of corrosion or damage.

However, some drawbacks exist. Installation may require expertise, limiting their accessibility for all users. Additionally, while they offer longevity, they can be costly upfront. Balancing these factors is essential when considering their use in specific applications. Understanding both the advantages and limitations helps in making informed decisions.

When considering valve options, cost-effectiveness is vital. Pilot operated diaphragm valves offer notable savings over time. According to industry reports, these valves reduce energy consumption by approximately 20%. This can translate to major savings for large facilities.

Maintenance requirements are another advantage. These valves generally have fewer moving parts. Consequently, they often require less routine maintenance. A surveyed group of facility managers noted a 30% decrease in maintenance costs when shifting to diaphragm valves. They appreciated the longer lifespan, reducing replacement frequency.

However, not all applications benefit equally. Some users reported challenges in specific conditions, leading to frustration. It's essential to evaluate your unique needs before making a switch. This careful assessment can prevent wasted resources and ensure optimal performance.